Environmental Monitoring System through Groundwater Monitoring Well Development at Paiton Power Station

Monitoring Well Development for Groundwater and Environmental Integrity

Client: PT Paiton Operation & Maintenance Indonesia (POMI)

Location: Paiton, East Java, Indonesia

Year: 2019

Project Overview

PT Paiton Operation & Maintenance Indonesia (POMI), operator of Units 3, 7, and 8 of the Paiton Power Station, identified the need to strengthen its groundwater and environmental monitoring system. In the ash disposal area, a network of wells provides critical data on groundwater quality, ensuring compliance with environmental standards and protecting surrounding ecosystems. When Monitoring Well MW-1 ceased to function, POMI initiated a program to decommission the old well and construct a replacement well, MW-1A.

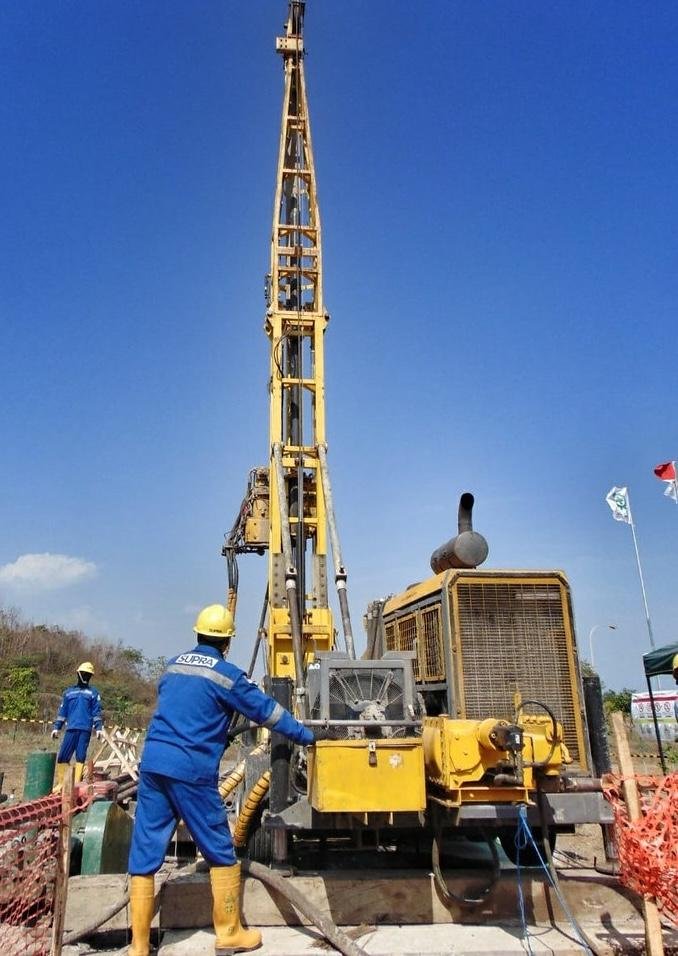

SUPRA International was engaged to support the project with technical execution that emphasized both engineering integrity and environmental safeguards. The objective was not limited to constructing a new well, but also to ensure the responsible closure of MW-1 to eliminate risks of cross-contamination.

Environmental and Technical Context

Coal-fired power generation facilities carry an inherent responsibility to manage by-products such as ash, which may leach contaminants into the soil and groundwater if left unchecked. A robust network of monitoring wells is therefore a frontline tool for early detection and environmental risk management.

The failure of MW-1 posed two significant risks: loss of monitoring capacity and the potential for the unused well to act as a conduit for contamination. Proper decommissioning of the old well was a prerequisite to ensuring the reliability of the replacement well, maintaining data accuracy, and safeguarding environmental compliance.

SUPRA’s Intervention

SUPRA delivered the intervention in two phases:

- Removal of old PVC casing and bottom plugs.

- Re-drilling and cleaning to eliminate debris and sand.

- Full sealing of the well using a cement–sand mixture of higher density and viscosity, designed to counter circulation losses and collapsed formations.

- Controlled cement placement via tremie pipes to achieve bottom-up filling, verified by cement overflow at the surface.

- Drilling and installation of a new monitoring well designed for long-term reliability

- Implementation of construction and safety protocols aligned with POMI’s environmental management framework.

- Integration of the well into the groundwater monitoring network, restoring system redundancy and ensuring continuity of data collection.

Challenges and Solutions

- Formation Instability: Collapsed formations and circulation losses complicated the sealing process. SUPRA adapted the cementing method to increase density and viscosity, ensuring volumetric integrity.

- Contamination Risk: The intervention was executed with strict containment protocols to prevent legacy contamination from MW-1 affecting aquifers or the new MW-1A.

- Regulatory Standards: All works were aligned with environmental and safety requirements, including site safety inductions, PPE compliance, and adherence to POMI’s contractor safety policies.

Business and Environmental Impact

The project reinforced PT POMI’s environmental stewardship and operational compliance:

- Environmental Assurance: By eliminating contamination pathways, POMI ensured long-term protection of groundwater quality in the ash disposal area.

- Monitoring Reliability: Restoring a fully functional well network supported accurate data collection for environmental reporting and compliance with Indonesian regulations.

- Risk Mitigation: Proper decommissioning reduced liabilities associated with abandoned infrastructure, safeguarding against regulatory or community challenges.

- Operational Continuity: The new MW-1A well ensured that the power station could continue to demonstrate responsible ash management as part of its sustainability commitments.

Highlight

SUPRA’s work at PT POMI Paiton site by delivering technical well construction and decommissioning that can be integrated into a broader environmental management strategy. The project delivered infrastructure and monitoring systems by ensuring the safe closure of MW-1 and the commissioning of MW-1. The project finished with contamination risks are minimized, and compliance with environmental obligations is sustained.

Share:

Jika Anda menghadapi tantangan dalam air, limbah, atau energi, SUPRA siap mendukung. Tim kami membantu meningkatkan keandalan, memastikan kepatuhan, meningkatkan efisiensi, dan mengendalikan biaya. Bersama, kita menentukan fase layanan lifecycle yang paling sesuai untuk kebutuhan proyek Anda.