Emergency Water Well Development: Best Practices and Technical Guidelines for Post-Disaster Clean Water Provision

Emergency Water Well Development: Best Practices and Technical Guidelines for Post-Disaster Clean Water Provision

Reading Time: 75 minutes

Key Highlights

• Critical Timeframes: Emergency water supply must be established within 24-72 hours post-disaster to prevent waterborne disease outbreaks, with minimum 7.5-15 liters per person daily for survival increasing to 20-50 liters for basic hygiene and cooking once emergency phase transitions to recovery

• Technology Selection Matrix: Hand-dug wells (depth 5-20 meters) provide rapid deployment for shallow water tables within 3-7 days, while borehole drilling (20-150 meters) achieves higher yields and better water quality requiring 5-14 days construction but accessing deeper protected aquifers

• Water Quality Imperatives: WHO guidelines require turbidity <5 NTU, fecal coliform 0 CFU/100ml, and total coliform <10 CFU/100ml for emergency water supply, with point-of-use chlorination (1-2 mg/L residual) providing rapid disinfection when source quality uncertain or distribution contamination risks exist

• Resource Requirements: Typical emergency well program serving 10,000 affected population requires USD 50,000-200,000 budget covering 10-20 wells, drilling equipment mobilization, pumping systems (hand pumps USD 200-500, motorized USD 2,000-8,000), water quality testing, and chlorination supplies for 3-6 month emergency period

Essential Emergency Water Supply Technical Resources

WHO/UNECE: Guidance on Water Supply in Extreme Weather Events

Comprehensive 163-page technical guidance covering emergency water supply planning, alternative source development including wells and boreholes, water treatment technologies, distribution systems, quality assurance, and institutional arrangements for disaster response. Authoritative reference from World Health Organization and UN Economic Commission for Europe.

Download WHO/UNECE Guide (PDF - 163 pages)Global WASH Network: Emergency Water Supply Compendium

Technical compendium covering 25+ water supply technologies for humanitarian emergencies including groundwater development, well construction methods, pumping systems, water treatment, storage, and distribution. Practical guidance with decision matrices, cost estimates, and implementation procedures for field practitioners.

Download WASH Compendium (PDF)US EPA: Planning for Emergency Drinking Water Supply

Systematic planning guide for emergency water supply addressing source identification and assessment, alternative supplies including wells and boreholes, treatment and disinfection, storage and distribution, water quality monitoring, and contingency planning. Technical reference from US Environmental Protection Agency.

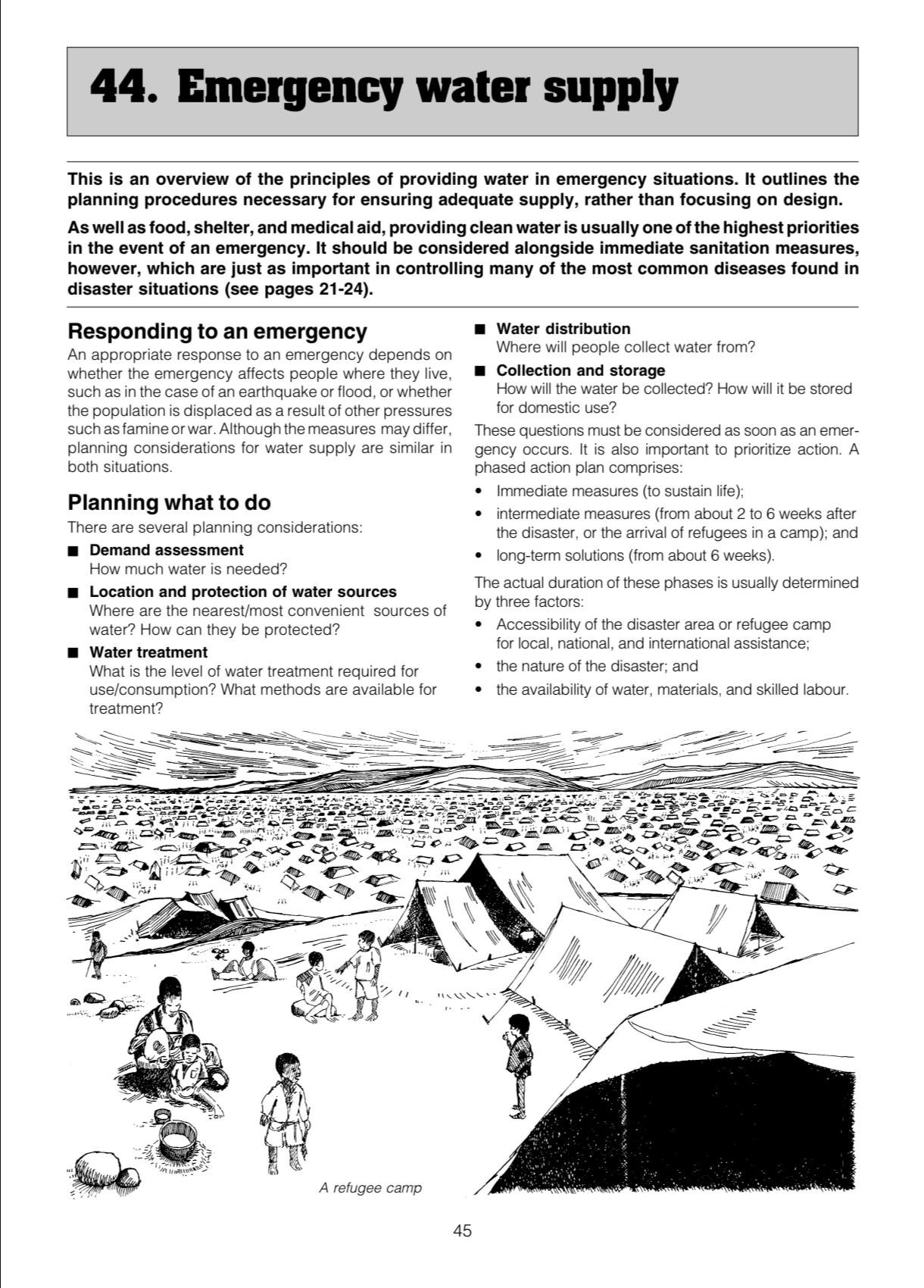

Download EPA Planning Guide (PDF)Livestock Emergency Guidelines: Emergency Water Supply (Reed & Shaw)

Detailed technical chapter covering emergency water source development including hydrogeological assessment, well siting and construction, infiltration galleries, spring protection, pumping systems, and water quality management. Practical field guidance with technical specifications and implementation procedures.

Download LEG Water Supply Guide (PDF)CDC: Emergency Water Supply Planning for Hospitals

Comprehensive planning guide for institutional emergency water supply covering demand assessment, alternative sources including wells, treatment systems, storage, distribution, quality monitoring, and contingency planning. Applicable to hospitals, health facilities, and essential services requiring reliable emergency water.

Download CDC Hospital Guide (PDF)Sphere Handbook: Humanitarian Charter and Minimum Standards (Bahasa Indonesia)

International humanitarian standards including WASH minimum standards for disaster response: water supply quantity and quality requirements, sanitation facilities, hygiene promotion, and technical guidelines. Indonesian language edition covering water supply, excreta disposal, vector control, and solid waste management in emergencies.

Download Sphere Handbook Bahasa Indonesia (PDF)Executive Summary

Natural disasters including earthquakes, floods, tsunamis, cyclones, and droughts disrupt water supply infrastructure serving millions of affected populations requiring rapid deployment of emergency water sources to prevent waterborne disease outbreaks and meet basic survival needs. Groundwater development through emergency well construction constitutes primary response strategy in disaster contexts where surface water contaminated, piped distribution systems damaged, or existing sources inadequate for expanded demand from displaced populations concentrated in temporary settlements. Emergency water supply operations must balance speed of deployment against technical quality and sustainability, with hand-dug wells, boreholes, and tube wells providing varying tradeoffs between construction time, yield capacity, water quality, and resource requirements depending on hydrogeological conditions, available equipment, technical capacity, and funding constraints affecting response effectiveness.

International humanitarian standards including Sphere Project establish minimum water supply requirements of 7.5-15 liters per person daily for survival needs during acute emergency phase, increasing to 20 liters for basic hygiene and domestic needs, and 50+ liters for optimal health and dignity once emergency phase transitions to recovery and rehabilitation programming. Water quality standards require absence of fecal contamination (0 fecal coliform per 100ml), free chlorine residual 0.5-1.0 mg/L at point of use, turbidity below 5 NTU, and reasonable taste, odor, and appearance. Emergency well development programs typically serve populations 500-10,000 persons per intervention through strategic placement of multiple wells reducing walking distances below 500 meters and queuing times below 30 minutes per Sphere standards, with infrastructure designed for 3-6 month emergency use while longer-term rehabilitation addresses sustainable water supply restoration through repair of pre-existing systems or permanent infrastructure development.

Emergency Water Supply Standards and Requirements

7.5-15 L/person/day

Drinking + food prep

20 L/person/day

+ basic hygiene

50+ L/person/day

+ laundry, bathing

500 meters

Walking distance

This comprehensive technical guide examines emergency water well development best practices covering hydrogeological assessment and site selection, well design and construction methods spanning hand-dug wells to mechanized boreholes, pumping systems selection and installation, water quality testing and treatment, operation and maintenance procedures, regulatory compliance and coordination mechanisms, resource mobilization and logistics, monitoring and evaluation frameworks, and case studies from major disaster responses demonstrating effective implementation approaches and lessons learned. Analysis targets humanitarian practitioners, water engineers, disaster management authorities, and development organizations implementing emergency water supply programs providing actionable guidance grounded in international standards, field-tested methodologies, and accumulated experience from disaster responses across diverse geographical and institutional contexts worldwide.

Emergency Water Supply Context and Planning Framework

Disasters disrupt water supply through multiple mechanisms including physical damage to wells, pumps, pipes, and treatment facilities; contamination of water sources from flood waters, sewage, chemical spills, or saline intrusion; power outages disabling pumping and treatment systems; displacement of populations to areas lacking adequate water infrastructure; and overwhelmed capacity as survivors concentrate in accessible areas or planned settlements. Initial assessment within 24-48 hours of disaster onset determines extent of infrastructure damage, status of water sources, affected population numbers and locations, priority needs, existing capacities, and resource gaps informing response strategy and intervention prioritization. Assessment teams including water engineers, hydrogeologists, and public health specialists conduct rapid surveys using structured assessment tools documenting pre-disaster water supply systems, damage extent, current water access, water quality concerns, and immediate response requirements feeding into coordinated response plans developed through humanitarian coordination mechanisms.

Emergency response timeline follows phased approach with immediate response (0-3 days) focusing on water trucking and bottled water distribution meeting basic survival needs, short-term response (3-30 days) establishing emergency wells, bladder tanks, and treatment systems providing sustainable access, and medium-term response (1-6 months) rehabilitating damaged infrastructure and developing permanent water sources supporting transition from emergency to recovery programming. Well development timeline varies by technology and conditions with hand-dug wells achievable in 3-7 days for shallow water tables using labor-intensive methods, machine-drilled boreholes requiring 5-14 days including mobilization and completion, and tube wells installed in 1-3 days where suitable hydrogeological conditions exist and equipment available. Multiple well construction teams working simultaneously across affected area enables population-wide coverage within 2-4 week timeframe meeting Sphere standards while addressing immediate health risks from inadequate water access or poor quality sources.

Emergency Water Supply Planning Components:

Needs Assessment and Prioritization:

• Affected population estimation: numbers, locations, demographic profile (vulnerable groups)

• Baseline water access: pre-disaster sources, current functionality, damage extent

• Water availability: walking distances, queuing times, daily per capita access

• Water quality concerns: contamination risks, reported illnesses, laboratory testing

• Priority populations: health facilities, nutrition centers, collective shelters, vulnerable groups

• Geographic priorities: highest population concentrations, most severe access gaps

Resource Assessment and Mobilization:

• Existing capacities: local drillers, equipment, materials, technical expertise

• Government resources: public works departments, military engineering, national stocks

• NGO and UN assets: specialized agencies, standby partnerships, procurement mechanisms

• Commercial sector: local suppliers, regional contractors, international procurement

• Funding sources: emergency response funds, donor appeals, government allocations

• Logistics constraints: access routes, storage facilities, customs clearance, security

Technical Strategy Development:

• Technology selection: well types, depths, yields matching hydrogeology and requirements

• Site identification: hydrogeological assessment, social considerations, land access

• Water quality approach: source protection, treatment requirements, distribution methods

• Sustainability planning: operations and maintenance, institutional arrangements, exit strategy

• Environmental considerations: wastewater disposal, aquifer sustainability, ecosystem impacts

• Standards and specifications: technical designs, construction standards, quality assurance

Coordination and Implementation:

• Cluster coordination: WASH cluster participation, information sharing, response coordination

• Government liaison: line ministry collaboration, permitting, technical standards

• Community engagement: consultation, site selection, management committees, hygiene promotion

• Monitoring systems: construction oversight, water quality testing, access monitoring

• Reporting mechanisms: situation reports, dashboards, beneficiary tracking, donor reporting

• Adaptive management: learning reviews, strategy adjustment, scale-up or transition planning

Hydrogeological conditions fundamentally determine feasible well development approaches and expected outcomes. Shallow unconsolidated aquifers (alluvial deposits, weathered rock) at depths 5-20 meters enable hand-dug well construction using labor-intensive methods requiring minimal equipment, suitable where water tables high and geological materials permit manual excavation through clay, sand, or soft rock without excessive water inflow or collapse risk during construction. Deeper or more consolidated formations require machine drilling using rotary, percussion, or down-the-hole hammer methods penetrating hard rock, thick clay layers, or reaching productive aquifers at depths 20-150 meters, providing higher yields and often better water quality from protected formations but requiring specialized equipment, technical expertise, and longer construction timelines. Rapid hydrogeological assessment using existing geological maps, pre-disaster well inventories, community knowledge, surface indicators (vegetation, topography, existing wells), and if possible geophysical surveys (electrical resistivity, seismic refraction) guides site selection and technology matching ensuring realistic expectations and efficient resource deployment avoiding failed wells or inadequate yields from mismatched approaches.

Hand-Dug Wells: Rapid Deployment for Shallow Aquifers

Hand-dug wells constitute rapid, low-cost emergency water source development for shallow water tables in unconsolidated formations where manual excavation feasible without excessive dewatering, collapse risk, or hazardous gas accumulation. Typical construction employs 4-6 laborers excavating circular shaft 1.0-1.5 meters diameter to depth 5-20 meters through manual digging using picks, shovels, and buckets, with temporary casing or lining preventing collapse during excavation and permanent lining of concrete rings, brick masonry, or stone providing structural stability and sanitary protection post-construction. Construction timeline averages 5-10 days depending on depth, soil conditions, water inflow, and lining method, with costs typically USD 500-3,000 per well covering labor, materials, casing, and simple handpump installation. Yields range 0.5-5 m³/hour (8-80 liters/minute) sufficient for populations 100-500 persons with handpump or small motorized pump, with higher yields possible in very permeable formations or where large-diameter wells constructed enabling gravity drainage from surrounding aquifer.

Hand-Dug Well Construction Specifications

| Parameter | Specification | Purpose/Rationale |

|---|---|---|

| Well Diameter | 1.0-1.5 meters | Allow worker entry, equipment use, adequate yield; larger diameter increases cost |

| Depth Range | 5-20 meters typical | Hand excavation limit; deeper requires dewatering, safety risks increase |

| Lining Thickness | 100-200mm concrete/brick | Structural stability, prevent collapse, sanitary protection |

| Sanitary Seal | 3-5m from surface | Prevent surface contamination entry through cracks or joints |

| Apron/Platform | 1-1.5m radius concrete | Surface water drainage, prevent contamination, structural support |

| Cover/Headworks | Sealed concrete slab | Exclude contaminants, debris, animals; pump mounting |

| Screen Section | Lower 1-3 meters | Allow water entry while excluding sand/gravel; perforated/porous lining |

| Gravel Pack | 150-300mm annulus | Filter fine particles, prevent sand pumping, increase yield |

Site selection for hand-dug wells balances hydrogeological suitability, accessibility, safety, and social considerations. Hydrogeological screening identifies areas with shallow water tables (<15 meters preferred, <20 meters maximum), suitable geology permitting excavation without excessive water inflow during construction or collapse risk (avoid quicksand, boulder layers, very soft clays), adequate aquifer thickness and permeability supporting required yields, and groundwater quality concerns (distance from pollution sources, salinity, naturally occurring contaminants). Social considerations include proximity to beneficiary populations reducing walking distances below 500 meters, land access and ownership avoiding conflicts or restricted access, security enabling safe construction and use particularly for women and children, and community acceptance with input on site selection and management arrangements. Safety considerations require minimum 10-meter distance from latrines, septic systems, or solid waste disposal; 30-meter buffer from surface water bodies preventing contamination from either direction; elevated location avoiding flood inundation; and stable ground preventing settlement or landslides damaging well structure.

Hand-Dug Well Construction Procedure:

Phase 1: Site Preparation and Excavation Start (Day 1-2):

• Mark well location, clear vegetation and topsoil 3-meter radius

• Excavate starter pit 1.5 meter diameter, 2 meters deep using circular template

• Install first concrete ring or temporary casing preventing upper soil collapse

• Establish safety protocols: ventilation checking, ladder access, communication system

• Set up dewatering if needed: sump and pump removing water accumulation

• Organize material stockpiles: casing rings, cement, aggregates, tools

Phase 2: Shaft Excavation (Day 2-6):

• Continue circular excavation using picks and shovels, 4-6 hour shifts

• Remove excavated material using bucket and rope or tripod winch

• Install additional lining rings (concrete, brick, stone) as excavation progresses

• Maintain vertical alignment using plumb bob or spirit level

• Monitor for hazardous gases using flame test or gas detector

• Implement ventilation: forced air if depth >10 meters or stagnant conditions

• Dewater continuously if groundwater inflow exceeds 0.5 m³/hour

• Stop excavation when reaching productive aquifer: 2-3 meters into water-bearing zone

Phase 3: Well Completion and Development (Day 7-8):

• Install screen section: perforated concrete rings or gravel-packed lower section

• Place gravel pack in annular space between excavation and lining

• Seal upper 3-5 meters: clay or cement grout preventing surface contamination

• Develop well: remove fine particles by surging and pumping improving yield

• Install permanent pump: handpump or motorized system with rising main

• Construct headworks: concrete cover slab, apron, drainage channel

Phase 4: Finishing and Commissioning (Day 9-10):

• Allow concrete to cure minimum 3 days before use

• Chlorinate well: dose with 50-100 mg/L chlorine, stand 12-24 hours, flush

• Test water quality: microbiological (coliform), physical-chemical (basic parameters)

• Conduct pump test: measure yield, drawdown, recovery assessing performance

• Install fence or barrier preventing animal access within 3-meter radius

• Community handover: train management committee, establish maintenance arrangements

• Document construction: location, depth, yield, water quality, completion date

Safety during hand-dug well construction requires strict protocols as confined space work presents multiple hazards including collapse, flooding, asphyxiation, and falling objects. All wells require competent person supervision with confined space entry training, daily pre-entry atmosphere testing for oxygen deficiency and toxic gases (carbon monoxide, hydrogen sulfide, methane), continuous ventilation using forced air blowers for depths exceeding 10 meters, secure ladder or rope access with safety harness for workers in shaft, and emergency rescue equipment including rope, harness, and tripod readily available. Cave-in prevention through immediate installation of temporary or permanent lining as excavation progresses, with maximum 1 meter unlined excavation at any time and continuous monitoring for ground movement or water inflow indicating instability. Workers limited to 4-6 hour shifts in shaft with surface rotation preventing fatigue, dehydration, or heat stress, particularly in tropical climates where shaft temperatures may exceed 35-40°C at depth. Emergency response plans addressing potential incidents including collapse, flooding, or medical emergencies with communication system (whistle, radio), first aid kit, and evacuation procedures pre-established before commencing excavation.

Borehole Drilling: High-Yield Deep Groundwater Access

Borehole drilling using mechanized equipment accesses deeper aquifers (20-150 meters typical, up to 300+ meters in some formations) providing higher yields, better water quality from protected formations, and more reliable year-round supply compared to shallow hand-dug wells. Three primary drilling methods suit emergency contexts: cable tool percussion drilling using repeated impact of heavy drill bit to crush rock, suitable for consolidated formations and water-bearing zones requiring minimal fluid; rotary drilling using rotating bit with circulating drilling fluid (mud or air) cutting through formations and removing cuttings, fastest method for unconsolidated to moderately hard formations; and down-the-hole (DTH) hammer drilling using pneumatic hammer behind bit for hard rock, combining penetration speed of percussion with hole straightness of rotary methods. Drilling contractor selection considers equipment availability, experience in similar geology, capacity for rapid mobilization, and costs typically USD 15-50 per meter drilling plus USD 2,000-8,000 completion (casing, screen, grout, development), with total borehole costs USD 3,000-15,000 depending on depth, diameter, geology, and location.

Drilling Method Selection and Performance

| Drilling Method | Suitable Formations |

Penetration Rate |

Depth Capability |

Advantages & Applications |

|---|---|---|---|---|

| Cable Tool Percussion | All formations | 2-10 m/day | 50-200m | Minimal water needs, identifies water-bearing zones, boulder penetration |

| Rotary Mud/Air | Soft to medium rock | 10-50 m/day | 50-300m | Fast in suitable geology, large diameter possible, continuous drilling |

| DTH Hammer | Hard rock | 15-40 m/day | 50-500m | Fast hard rock penetration, straight holes, crystalline rock aquifers |

| Auger Drilling | Unconsolidated only | 10-30 m/day | 10-50m | Simple, low cost, environmental, limited to soft formations |

| Hand Auger/Jetting | Sand, soft clay | 5-15 m/day | 5-30m | Very low cost, no machinery, community participation possible |

Borehole design specifications balance hydrogeological conditions, required yield, water quality objectives, and construction practicalities. Total depth determined by productive aquifer depth plus sufficient penetration (minimum 5-10 meters into water-bearing zone, deeper if possible improving yield and reliability), with drilling continuing until adequate yield achieved or maximum planned depth reached. Borehole diameter typically 150-300mm (6-12 inches) at bottom, potentially larger upper sections enabling nested casing installation, with diameter selection balancing drilling costs (increasing with diameter), pump accommodation (submersible pumps requiring minimum 100mm, larger pumps needing 150-200mm), and yield capacity (larger diameter provides greater screen area improving yield in low-permeability formations). Casing program includes surface casing preventing near-surface collapse and sealing sanitary zone (typically steel or PVC 6-20 meters depth), blank casing through non-productive zones, and screen in water-bearing formations (slot size selected based on aquifer grain size, screen length 20-40% of aquifer thickness, up-flushing development removing fines and improving well efficiency).

Borehole Construction and Completion:

Pre-Drilling Preparation:

• Site access: clear vegetation, create level pad, access road for drilling rig

• Water supply: 2,000-10,000 liters for drilling fluids (mud rotary) or dust suppression

• Material logistics: casing, screen, grout, development equipment on-site before drilling

• Technical specifications: target depth, casing program, screen specifications prepared

• Permits and approvals: drilling permits, water rights, land access secured

• Safety measures: first aid, fire extinguisher, emergency contacts, exclusion zone

Drilling Operations:

• Spud borehole and drill conductor hole to competent formation (typically 3-6 meters)

• Install surface casing and cement to surface preventing collapse and contamination

• Continue drilling to planned depth or until adequate water-bearing zone encountered

• Collect drill cuttings samples every 1-3 meters logging geology, water strikes

• Conduct test drilling to maximum depth verifying aquifer characteristics

• Borehole geophysical logging: electrical resistivity, natural gamma, caliper if available

• Drilling time: 5-10 days typical for 50-150 meter borehole including mobilization

Borehole Completion:

• Install blank casing and screen assembly: centralizers ensuring even annular space

• Place gravel pack around screen: size 2-4x aquifer D50, thickness 75-150mm

• Seal annular space above gravel pack: bentonite pellets or cement grout

• Sanitary seal: neat cement grout upper 6-10 meters preventing surface contamination

• Well development: surging, overpumping, air lifting removing fine particles

• Development duration: 6-24 hours until water clear and yield stabilized

• Test pumping: step-drawdown test determining optimal pump rate, capacity

Headworks and Commissioning:

• Cut casing to height: 300-600mm above ground preventing flood entry

• Install sanitary seal: concrete pad 1.5 meter radius, 150mm thickness

• Pump installation: submersible or surface pump sized to measured yield

• Electrical connection: generator or grid power with protection systems

• Chlorination: high-dose shock chlorination (100 mg/L), 24-hour contact, flush

• Water quality testing: microbiological and chemical analysis baseline

• Handover documentation: construction log, test data, operating instructions, maintenance schedule

Well development constitutes critical step improving yield and water quality through removal of fine particles introduced during drilling, opening natural fractures and pores, and stabilizing gravel pack preventing sand pumping during operation. Development methods include overpumping at rates 150-200% of planned operating rate removing fine particles, mechanical surging using plunger or surge block in screen section creating alternating inflow and outflow dislodging sediment, air lifting using compressed air injected to bottom creating turbulent flow, and combination approaches sequencing multiple methods. Development continues until suspended sediment content decreases below 50 mg/L (turbidity <25 NTU), yield stabilizes within 10% over 30-minute intervals, and visual inspection shows no sand entering well indicating gravel pack functioning properly. Rushed or inadequate development results in reduced yields (20-50% below potential), sand pumping damaging pumps and creating turbidity, and gradual performance decline requiring redevelopment or premature well abandonment, justifying investment in thorough development despite time and cost implications in emergency contexts.

Water Quality Assessment and Treatment Systems

Water quality testing constitutes essential component of emergency water supply ensuring microbiological and chemical safety prior to use, with testing frequency and parameters balanced against laboratory capacity, costs, and urgency of water access. Minimum testing includes microbiological analysis for fecal contamination indicators (E. coli or thermotolerant coliform, total coliform), turbidity as physical water quality indicator and treatment effectiveness measure, pH affecting disinfection efficacy and corrosivity, and residual chlorine confirming disinfection. Comprehensive testing adds chemical parameters including nitrate (>50 mg/L indicating contamination risk), fluoride (dental effects at >1.5 mg/L), arsenic (cancer risk >10 μg/L), salinity or electrical conductivity (taste and domestic use effects >1,500 μS/cm), and locally relevant parameters based on geological or contamination concerns. Field testing using portable kits provides rapid results within hours enabling immediate decisions on source suitability and treatment requirements, while laboratory analysis offers comprehensive assessment typically within 24-72 hours supporting long-term source selection and monitoring programs.

Emergency Water Quality Standards and Testing

| Parameter | WHO Guideline | Emergency Acceptable |

Health Significance |

Testing Method |

|---|---|---|---|---|

| E. coli / Fecal Coliform | 0 CFU/100ml | 0 CFU/100ml | Critical | Membrane filtration, Colilert, Petrifilm (24-48hr) |

| Turbidity | <5 NTU | <25 NTU | High | Turbidity meter (immediate) |

| Free Chlorine Residual | 0.2-0.5 mg/L | 0.5-2.0 mg/L | High | DPD colorimetric test (immediate) |

| pH | 6.5-8.5 | 6.0-9.0 | Medium | pH meter or test strips (immediate) |

| Nitrate (NO3-N) | <50 mg/L | <50 mg/L | Medium | Colorimetric field kit or lab analysis |

| Fluoride | <1.5 mg/L | <4.0 mg/L | Medium | Ion-selective electrode or lab |

| Arsenic | <10 μg/L | <50 μg/L interim | High | Field test kit or lab (ICP-MS) |

| Salinity (TDS/EC) | <600 mg/L TDS | <1,500 mg/L | Low | Conductivity meter (immediate) |

Testing Priority: Daily turbidity and chlorine residual monitoring. Weekly microbiological testing. Monthly comprehensive chemical analysis. Site-specific parameters based on geological and contamination risks.

Disinfection through chlorination represents primary treatment for microbiologically unsafe sources or preventing recontamination during storage and distribution. Point-of-source chlorination at wellhead using automatic dosing systems (erosion feeders, peristaltic pumps) or manual batch chlorination maintains 0.5-1.0 mg/L free chlorine residual throughout distribution protecting against contamination from containers, transport, or household storage. Chlorine dose calculation requires water demand (m³/day), contact time before use (minimum 30 minutes for bacteria, 60+ minutes for viruses in turbid water), and desired residual concentration accounting for chlorine decay during distribution. Typical dosing rates 2-5 mg/L initial dose achieving 0.5-1.0 mg/L residual after 30 minutes contact and distribution, with higher doses (up to 10 mg/L) required for turbid water or long distribution. Point-of-use household chlorination using dilute sodium hypochlorite solution (aquatabs, liquid bleach) provides backup disinfection where source treatment impossible or distribution contamination suspected, with clear instructions on dosage (typically 2-4 drops 5% bleach per liter or 1 tablet per specified volume) and contact time before consumption.

Emergency Water Treatment Technologies:

Chlorination Systems:

• Erosion chlorinators: tablets in flow-through canister, 0.5-5 m³/hour capacity, simple, no power

• Hypochlorite dosing pumps: automatic peristaltic or diaphragm pumps, solar or battery powered

• Batch chlorination: manual dosing to storage tanks, 30-60 minute contact before distribution

• Point-of-use methods: household water treatment using tablets, liquid bleach, sodium dichloroisocyanurate

• Chlorine supplies: calcium hypochlorite (HTH) 65-70% available chlorine, stable, long shelf life

• Sodium hypochlorite solution: 5-15% available chlorine, liquid dosing, shorter shelf life

Turbidity Reduction:

• Sedimentation: plain settling in tanks 2-4 hour retention, removes >70% turbidity >50 NTU

• Flocculation-settling: alum or ferric salts 10-50 mg/L, rapid mixing, settling, removes 80-95% turbidity

• Rapid sand filtration: downflow through 60-120cm sand bed, 2-5 m/hour, pretreatment if turbidity >50 NTU

• Slow sand filtration: 0.1-0.3 m/hour through 80-100cm fine sand, biological action, good for stable supply

• Bag/cartridge filters: disposable media, 1-50 micron ratings, low flow rates, simple

• Emergency clarification: locally available materials (moringa seeds, cactus pads) in resource-limited contexts

Comprehensive Treatment Trains:

• Package treatment plants: containerized systems 10-100 m³/hour, flocculation, settling, filtration, chlorination

• Membrane filtration: ultrafiltration (0.01 micron) or microfiltration (0.1 micron) removing bacteria, protozoa

• Mobile treatment units: trailer-mounted systems, rapid deployment, 20-200 m³/day capacity

• Household treatment: ceramic filters, biosand filters, SODIS, combined filtration-disinfection systems

• Solar disinfection: UV radiation in transparent bottles, 6 hours sunlight, free, limited scale

• UV disinfection: lamp systems for clear water, no chemical taste, requires power and maintenance

Treatment Selection Criteria:

• Water quality: match treatment to contaminants (turbidity, microbiological, chemical)

• Flow requirements: system capacity matching demand (consider peak vs average)

• Power availability: prefer gravity or solar systems where electricity unreliable

• Chemical supply: chlorine logistics, storage stability, transport constraints

• Technical capacity: operations complexity matching local skills and training opportunity

• Cost and sustainability: initial investment vs operating costs, spare parts, consumables

• Cultural acceptance: taste, odor, appearance, method familiarity, community preference

Chemical contamination requiring treatment proves challenging in emergency contexts given complexity and costs of appropriate technologies. Arsenic removal using adsorption media (activated alumina, iron oxide), coagulation-filtration, or reverse osmosis requires specialized systems, technical expertise, and substantial cost, typically beyond emergency response capacity unless pre-existing contamination known and planning conducted. Fluoride removal similarly requires ion exchange, activated alumina, or reverse osmosis, with emergency responses often relying on source blending diluting high-fluoride sources with low-fluoride sources or piped supplies. Salinity requires reverse osmosis or distillation, extremely expensive and energy-intensive, with emergency responses typically avoiding saline sources unless absolutely necessary and treatment feasible through mobile desalination units deployed to coastal areas. Nitrate contamination indicates fecal pollution risk requiring source improvement through better siting, sanitary protection, and possibly treatment through ion exchange or biological denitrification, though emergency responses typically abandon highly contaminated sources rather than attempting treatment given health risks and technical challenges. Overall approach prioritizes microbiologically safe water addressing immediate disease outbreak risks, with chemical parameters accepted temporarily above guidelines where alternatives unavailable while longer-term solutions developed during recovery phase.

Pumping Systems and Power Supply Options

Pump selection balances technical requirements (well yield, depth, head), power availability, maintenance implications, and costs ensuring reliable water delivery with minimal downtime. Handpumps constitute simplest option for low to moderate yields (5-20 liters/minute) from depths to 45 meters, requiring no external power, minimal maintenance, and proven reliability in emergency contexts with widespread spare parts availability and repair capacity. Popular designs include India Mark II (suction-piston pump, 7-45 meter depth range, 10-25 L/min output), Afridev (similar performance, improved maintenance design), and rope-and-washer pumps (simple construction, shallow wells <25 meters, 10-30 L/min, locally manufactured). Motorized pumps provide higher flows (1-50 m³/hour) from greater depths (up to 300+ meters), requiring electrical or engine power, fuel or electricity supply, skilled maintenance, and spare parts stocks, with submersible electric pumps dominating deeper boreholes given efficiency, reliability, and reduced maintenance compared to surface-mounted centrifugal or piston pumps requiring daily attention.

Pump Technology Selection Matrix

| Pump Type | Depth Range (m) |

Flow Rate (L/min) |

Power Source |

Cost Range (USD) |

Applications & Advantages |

|---|---|---|---|---|---|

| Handpumps (India Mark II) | 7-45 | 10-25 | Manual | 200-500 | Community supplies, no power, simple maintenance, proven design |

| Rope & Washer | 5-25 | 10-30 | Manual/motor | 50-300 | Shallow wells, locally manufactured, irrigation and domestic use |

| Solar Submersible | 10-150 | 50-500 | Solar PV | 3,000-12,000 | Off-grid sites, zero operating fuel, low maintenance, daylight pumping |

| Electric Submersible | 15-300 | 100-3,000 | Grid/generator | 800-8,000 | High flow, deep wells, reliable power available, standard technology |

| Diesel/Petrol Pump | 5-100 | 200-2,000 | Fuel engine | 500-5,000 | Portable, independent power, emergency pumping, fuel logistics needed |

| Wind Pumps | 10-80 | 50-300 | Wind | 3,000-15,000 | Windy areas, no fuel costs, intermittent pumping, niche application |

Solar-powered pumping systems offer excellent solution for off-grid emergency water supply eliminating fuel logistics while providing reliable operation in sunny climates typical of many disaster-prone regions. System comprises solar photovoltaic panels (typically 1-5 kW for community water supplies), pump controller regulating voltage and current, submersible pump matched to well characteristics and water demand, and often storage tank enabling water availability during night or cloudy periods. Sizing requires calculating daily water demand (population × per capita demand), pumping head (well depth + drawdown + surface elevation + friction losses), solar resource (peak sun hours 4-7 hours/day depending on latitude and season), and system losses (15-25% typical). Example: 1,000 persons × 20 L/day = 20 m³ daily demand, pumping from 50 meter depth with 10 meter drawdown and 5 meter surface head = 65 meter total head, requiring 2.5 kW solar array and 1.5 kW pump operating 6-8 hours at peak production. Capital costs USD 8,000-15,000 for complete system compare favorably with diesel pumping over 5-10 year lifecycle considering fuel, maintenance, and environmental benefits, with declining solar costs improving economics annually.

Pump Installation and Commissioning:

Handpump Installation (India Mark II example):

• Well preparation: clean borehole, install rising main (GI or PVC pipe 32-40mm), centralizers

• Cylinder installation: attach foot valve and cylinder at pump intake depth (typically 2-3 meters below static water level)

• Rising main connection: couple pipe sections, check threads and seals, full-length installation

• Pump body mounting: position over well, secure to concrete pedestal, plumb verification

• Rod connection: install pump rods connecting handle to cylinder piston

• Final assembly: install handle, fulcrum, and protective housing

• Testing and adjustment: check operation, adjust stroke length, verify no air leaks

• Installation time: 4-8 hours with 2-3 workers

Submersible Electric Pump Installation:

• Pump selection: match to well diameter (minimum 25mm clearance), flow and head requirements

• Power supply: electrical connection to grid or generator, proper sizing, protection devices

• Cable and pipe assembly: attach delivery pipe (HDPE, GI, or PVC), electrical cable, safety rope

• Lowering pump: use tripod or well rig, controlled descent, avoid cable/pipe damage

• Setting depth: position 3-5 meters below pumping water level preventing cavitation

• Wellhead completion: seal cable entry, install check valve, pressure gauge, flow meter

• Electrical connection: wiring to control panel, motor protection, on-off controls

• Testing: gradual startup, check rotation direction, measure flow and power consumption

• Installation time: 6-12 hours depending on depth and configuration

Solar Pumping System Installation:

• Site assessment: verify solar resource, pump specifications, mounting structures

• Array foundation: concrete pads or ground anchors for panel mounting frames

• Panel installation: mount at optimal tilt angle (typically latitude ±10°), secure connection

• Controller installation: weather-protected enclosure near panels, wiring to pump

• Pump lowering: same as electric submersible, cable to controller

• System commissioning: verify voltage and current, check operation at different solar conditions

• Storage tank connection: if included, plumbing and float valve automation

• User training: system operation, routine checks, maintenance requirements

• Installation time: 2-5 days including foundation curing

Maintenance and Spare Parts Planning:

• Preventive maintenance schedules: daily checks (operation), weekly (pumping rates), monthly (detailed inspection)

• Spare parts stock: pump seals, bearings, impellers, foot valves, pipe couplings (typically 10-20% of pumps)

• Tools and consumables: pipe wrenches, lifting equipment, grease, sealants, cable ties

• Maintenance training: operators, community technicians, backup support arrangements

• Service contracts: agreements with local suppliers or specialized agencies

• Performance monitoring: flow measurement, power consumption, downtime tracking

• Pump life expectancy: handpumps 10-15 years, submersibles 7-12 years, solar PV 20-25 years

Storage, Distribution, and Point-of-Use Management

Water storage proves essential in emergency contexts enabling continuous supply despite intermittent pumping, providing surge capacity for peak demands, and allowing treatment contact time for disinfection. Storage capacity typically sized for 1-2 days demand (population × per capita consumption × 1-2 days) balancing supply reliability against construction costs and land requirements, with 20-50% surplus for fire fighting, contingencies, or demand growth. Elevated tanks constructed from steel, fiberglass, or reinforced concrete provide gravity distribution eliminating pumping costs and improving pressure reliability, though requiring structural foundations and increased capital costs compared to ground-level storage. Ground storage tanks or bladders (flexible fabric tanks 5-100 m³ capacity) offer rapid deployment and lower costs suitable for emergency contexts, with booster pumping or tapstand at tank level providing distribution. Emergency contexts increasingly utilize modular bladder tanks deployed within days, filled by trucking or pumping, providing immediate supply while permanent wells and distribution systems constructed.

Distribution methods vary from centralized piped networks to decentralized tapstand clusters or individual jerrycan collection depending on settlement layout, duration, and resources. Temporary piped distribution using HDPE, PVC, or flexible hoses connects wells to tapstands spacing 200-500 meters enabling household collection, with design flow rates 0.2-0.5 liters/second per tapstand serving 200-500 persons assuming 8-12 hour daily operation. Tapstand design includes multiple faucets (4-8 typical) enabling parallel filling reducing queuing, concrete apron with drainage preventing mud and standing water, and protective fencing restricting animal access. Individual household connections prove appropriate for semi-permanent settlements or recovery phase where settlement planning allows orderly layout and longer-term occupation justifies infrastructure investment, with yard taps or house connections reducing collection labor particularly benefiting women and children traditionally responsible for water carrying. All distribution systems require residual chlorination maintaining 0.5-1.0 mg/L throughout network preventing contamination from pipe leaks, connections, or storage tanks.

Water Collection and Household Storage:

Container Selection and Management:

• Jerrycans (10-20 liter): standard emergency distribution, narrow opening limiting contamination

• Buckets and basins: wide-mouth enabling easier filling but higher contamination risk

• Clay pots or plastic drums: household storage 20-100 liters, covered preventing debris

• Collapsible containers: space-efficient when empty, lightweight, distribution logistics

• Material considerations: food-grade plastic, no previous chemical use, light color preventing heating

• Container hygiene: regular washing with soap and water, sun drying, chlorine rinse if contaminated

Household Water Treatment and Safe Storage (HWTS):

• Chlorination: sodium hypochlorite solution (WaterGuard, Aquatabs) 2-4 mg/L, 30 minute contact

• Filtration: ceramic filters, biosand filters, cloth filters (cholera prevention)

• Solar disinfection (SODIS): clear PET bottles, 6 hours sunlight, UVA inactivation

• Boiling: 1 minute rolling boil, fuel intensive, culturally acceptable, 100% pathogen removal

• Combination methods: filtration followed by chlorination maximizing protection

• Storage safety: covered containers, narrow opening, dispensing without hand contact

Water Collection Best Practices:

• Timing: collect during off-peak hours reducing queuing (early morning, midday)

• Cleanliness: rinse containers before filling, avoid contaminated faucets or floors

• Transport: covered during transport preventing contamination, minimize time to use

• Dedicated containers: separate drinking water from washing/cooking water

• Child safety: supervision at tapstands preventing drowning in open tanks

• Accessibility: priority for elderly, disabled, pregnant women, separate queues if needed

Monitoring and Behavior Change:

• Hygiene promotion: handwashing at critical times, safe food preparation, sanitation use

• Community mobilization: water committees, maintenance groups, hygiene volunteers

• Water quality surveillance: household storage monitoring, contamination source identification

• Usage monitoring: per capita consumption tracking, equitable access verification

• Feedback mechanisms: community complaints, service improvement consultations

• Behavior indicators: container coverage rates, treatment adoption, handwashing prevalence

Operations, Maintenance, and Sustainability Framework

Sustainable emergency water supply operations require institutional arrangements defining management responsibilities, financial mechanisms covering operating costs, technical capacity for maintenance and repairs, and community participation ensuring social sustainability and local ownership. Management models span community management with elected water committees responsible for operations and maintenance supported by external technical assistance, contracted operation where NGO or private company operates system with community oversight and government regulation, or public utility management integrating emergency supplies into municipal water authority jurisdiction enabling long-term institutional sustainability. Community management suits dispersed well systems serving 100-500 persons per source with simple handpump technology, minimal operating costs, and strong social cohesion enabling collective action. Contracted or utility management proves appropriate for larger systems, complex treatment or pumping infrastructure, or weak community organization requiring professional operations with technical expertise and financial management capacity.

Cost recovery mechanisms balance financial sustainability against affordability ensuring vulnerable populations access water despite limited ability to pay. Full cost recovery including capital amortization, operations, maintenance, and administration typically generates water tariffs USD 0.50-2.00 per m³, translating to USD 0.30-1.20 per household monthly for 20 liter/person/day consumption at 5-person household size, affordable for middle and upper income groups but potentially excluding poorest households earning

Operations and Maintenance Planning:

Routine Operations Procedures:

• Daily checks: pump operation, water levels, flow rates, chlorine residual, turbidity

• Weekly tasks: generator fuel and oil, electrical systems, pipe leaks, tapstand condition

• Monthly activities: comprehensive system inspection, water quality lab testing, cleaning

• Quarterly maintenance: pump servicing, electrical maintenance, storage tank cleaning

• Annual overhaul: pump removal and rebuild, well redevelopment if yield declining

• Record keeping: operations logs, maintenance records, water quality results, incident reports

Preventive Maintenance Schedules:

• Handpump maintenance: quarterly inspection, annual service (seals, bearings), 3-year major overhaul

• Submersible pumps: monthly monitoring (power, flow), annual professional service, 5-7 year replacement

• Solar systems: monthly cleaning panels, quarterly controller check, annual electrical inspection

• Storage tanks: weekly level monitoring, quarterly internal inspection, annual cleaning/disinfection

• Distribution network: daily pressure monitoring, weekly leak detection, monthly valve operation

• Treatment systems: daily chemical dosing, weekly equipment calibration, monthly membrane cleaning

Spare Parts and Tools Inventory:

• Critical spares: pump seals and bearings, foot valves, pipe couplings, electrical contactors

• Consumables: chlorine supply (3-6 month stock), water quality test supplies, lubricants

• Tools: pipe wrenches, multimeter, lifting tripod, submersible pump puller

• Safety equipment: harnesses, gas detector, first aid kit, fire extinguisher

• Stock levels: 10-20% spare pumps, 6-12 month consumable supplies

• Logistics: secure storage, inventory management, procurement procedures

Capacity Building and Training:

• Pump mechanics: 2-5 day training on pump installation, maintenance, troubleshooting

• Operators training: system operation, chlorination, water quality testing, record keeping

• Community committees: financial management, conflict resolution, reporting

• Gender considerations: female participation in committees and technical roles

• Refresher training: annual reviews, new technology orientation

• Technical backstopping: ongoing support from implementing agency or government

Case Studies: Emergency Water Supply Responses

Case Study 1: 2004 Indian Ocean Tsunami - Aceh, Indonesia

Disaster Context: December 26, 2004 tsunami devastated Aceh Province coastal areas killing 170,000+ persons, displacing 500,000+, and destroying water infrastructure including wells, pipes, and treatment facilities. Flooding contaminated shallow groundwater with seawater, sewage, and debris. Survivors concentrated in displacement camps lacking water supply.

Emergency Response (0-3 months):

• Water trucking: 2-5 liters/person/day initial supply via tank trucks to camps and accessible villages

• Well assessment: rapid survey 500+ wells documenting damage, salinity, functionality

• Emergency repairs: cleaning, disinfection, pump repair 100+ existing wells within 6 weeks

• New well construction: 200+ hand-dug wells and boreholes in camps and return areas

• Water treatment: distribution of water purification tablets, household filters, chlorination supplies

Technical Approach:

• Drilling program: combination rotary and DTH drilling accessing 30-80 meter aquifers beneath saline zone

• Pumping systems: handpumps for community wells, motorized for larger camps and health facilities

• Water quality: extensive testing revealing salinity extent (up to 2 km inland), gradual freshening

• Treatment: central chlorination of piped supplies, household treatment for dispersed wells

• Coordination: WASH cluster coordination among 30+ responding agencies standardizing approaches

Medium-term Recovery (3-18 months):

• Permanent housing water supply: individual and communal wells integrated into reconstruction

• Piped water rehabilitation: repair and reconstruction 15 piped water systems serving towns

• Institution building: training local drillers, mechanics, operators, water committees

• Government capacity: restoring provincial water authority capacity for long-term management

Lessons Learned:

• Salinity assessment critical: electromagnetic conductivity surveys mapped extent enabling well siting

• Depth requirements: shallow wells (<15m) remained saline 12+ months; boreholes >30m productive

• Community engagement: consultation on well locations, technology choices improved acceptance

• Standards and coordination: technical standards through WASH cluster improved quality, avoided duplication

• Sustainability challenges: handpump spare parts supply, community management capacity, transitioning to government

Case Study 2: 2010 Haiti Earthquake - Port-au-Prince and Surroundings

Disaster Context: January 12, 2010 earthquake magnitude 7.0 struck Port-au-Prince killing 220,000+, displacing 1.5 million to camps, and destroying or damaging water infrastructure. Pre-existing water coverage only 30% urban areas; earthquake severely reduced remaining capacity.

Emergency Response (0-6 months):

• Water trucking: peak delivery 15 million liters daily (10 L/person/day) to 1,000+ distribution points

• Bladder tanks: deployment 500+ flexible tanks (10-50 m³) providing storage at distribution sites

• Wells and boreholes: emergency drilling 300+ new wells, rehabilitation 200+ existing sources

• Treatment: establishment 50+ water treatment points using chlorination, filtration

• Cholera response: October 2010 outbreak requiring massive scale-up chlorination, hygiene promotion

Technical Approach:

• Rapid drilling: mobilization international drilling contractors given limited local capacity

• Hydrogeology: alluvial aquifers 10-40 meters depth, adequate yields 5-20 m³/hour typical

• Borehole design: 6-inch diameter, PVC casing and screen, submersible pumps, solar where feasible

• Chlorination: automated dosing systems at source, distribution point treatment, household products

• Water quality: intensive monitoring given cholera risk, 2,000+ samples weekly during outbreak

Challenges Encountered:

• Urban drilling: congestion, rubble, underground utilities complicated siting and access

• Power supply: limited electricity requiring diesel generators, high operating costs

• Coordination: 400+ responding organizations requiring extensive coordination mechanisms

• Cholera outbreak: 800,000+ cases over 10 years, ongoing water quality challenges

• Sustainability: limited cost recovery, weak institutions, donor dependency

Lessons Learned:

• Preparedness value: pre-positioned drilling equipment would have accelerated response

• Urban challenges: drilling in dense urban areas requires specialized planning and equipment

• Power reliability: solar systems proved valuable given unreliable grid and diesel costs

• Cholera prevention: emergency water supply quality critical - single contaminated source sparked epidemic

• Long-term planning: emergency supplies should integrate into reconstruction plans not parallel systems

Case Study 3: 2013 Typhoon Haiyan (Yolanda) - Philippines

Disaster Context: November 8, 2013 Super Typhoon Haiyan struck Eastern Visayas with 315 km/h winds and 5-meter storm surge killing 6,300+, affecting 14 million persons, damaging or destroying water systems serving 4+ million people. Tacloban City and coastal communities severely impacted.

Emergency Response (0-3 months):

• Rapid assessment: water system damage surveys 400+ communities within 2 weeks

• Emergency water trucking: 5-10 liters/person/day initial supply to accessible areas

• Quick repairs: rehabilitation 500+ wells, springs, rainwater systems within 4 weeks

• New construction: installation 800+ wells and water points serving 500,000+ persons

• Treatment: distribution 2 million water purification tablets, 50,000+ household filters

Technical Approach:

• Technology mix: shallow wells (<15m) via hand digging, deeper boreholes (20-50m) via machine drilling

• Rapid construction: pre-fabricated handpumps, simplified designs enabling 3-5 day installation

• Solar pumping: deployment 100+ solar systems for off-grid communities

• Spring development: protection and gravity distribution for mountainous inland areas

• Piped system rehabilitation: gradual repair urban systems as power restored and pipes replaced

Recovery Phase (3-24 months):

• Build Back Better: reconstruction to higher standards, elevated infrastructure, backup systems

• Climate resilience: flood-resistant designs, protected intakes, emergency preparedness plans

• Decentralization: reducing dependency on single sources through diverse supply portfolio

• Community management: strengthening local water committees, operations training

• Government capacity: rehabilitation provincial and municipal water authorities

Lessons Learned:

• Storm surge impacts: coastal groundwater contamination by seawater required deeper wells or alternative sources

• Solar effectiveness: solar pumping eliminated fuel logistics in damaged infrastructure contexts

• Standards importance: rushed construction without quality assurance led to 20-30% early failures

• Community participation: engaging communities in site selection, technology choice improved outcomes

• Preparedness value: provinces with pre-disaster water sector development plans recovered faster

Case Study 4: 2011-2012 Horn of Africa Drought - Somalia, Kenya, Ethiopia

Disaster Context: Severe drought 2011-2012 affecting 13+ million people across Horn of Africa. Failed rains, livestock deaths, crop failures, and displacement to camps and urban areas. Somalia particularly impacted with famine declaration July 2011 in southern regions.

Emergency Response Characteristics:

• Context challenges: ongoing conflict limiting access, weak governance, limited infrastructure

• Water sources: reliance on boreholes given surface water depletion, well depths 50-300 meters

• Pastoralist needs: balancing human consumption with livestock watering requirements

• Urban influx: rapid population growth overwhelming existing systems Mogadishu, Dadaab camps

• Long duration: multi-year response requiring sustained operations not short-term emergency

Technical Interventions:

• Borehole rehabilitation: restoring 500+ non-functional wells, replacing pumps, redevelopment

• New drilling: 200+ new boreholes accessing deep aquifers, strategic siting near settlements

• Solar conversion: retrofitting 300+ diesel pumps to solar reducing operating costs

• Water trucking: 50 million liters weekly peak delivery to camps and drought-affected areas

• Shallow wells: hand-digging 1,000+ scoop wells in dry riverbeds (temporary seasonal sources)

Sustainability Innovations:

• Community borehole management: training caretakers, establishing water fees, spare parts funds

• Solar systems: eliminating fuel dependency, reducing operating costs 80-90%

• Hydrogeological assessment: groundwater mapping informing strategic well siting

• Pipeline extensions: connecting boreholes to settlements via 5-20 km pipelines

• Storage investment: strategic reserves enabling water trucking during peak drought

Lessons Learned:

• Preparedness critical: early warning systems enabling pre-positioning reduced mortality

• Solar cost-effectiveness: eliminating diesel fuel logistics in remote areas game-changing

• Community management: local caretakers with spare parts and training maintained functionality

• Hydrogeology investment: professional assessment reduced drilling failures from 30% to <10%

• Long-term perspective: treating recurring drought as chronic situation not one-off emergency

Regulatory Framework and Quality Assurance

Emergency water supply operates within regulatory frameworks balancing urgent response needs against technical standards ensuring public health protection and infrastructure quality. National water quality standards provide baseline requirements typically aligned with WHO guidelines, though emergency contexts may temporarily accept relaxed parameters where alternatives unavailable (turbidity <25 NTU vs standard <5 NTU; total coliform <10 CFU/100ml vs standard 0 CFU/100ml) while maintaining zero tolerance for fecal contamination given immediate disease risks. Construction standards for wells and boreholes follow national codes or international guidance (Sphere, UNICEF, World Bank) specifying minimum sanitary protection (concrete apron, drainage, minimum distances from contamination sources), structural requirements (casing depth and material, grouting specifications, well development), and pumping system specifications ensuring appropriate technology selection and installation quality. Quality assurance mechanisms include technical review of designs, construction supervision, completion testing, and commissioning verification before handover to communities or operators.

Coordination mechanisms through WASH (Water, Sanitation, and Hygiene) Cluster bring together government, UN agencies, NGOs, and donors aligning response strategy, sharing information, avoiding duplication, and establishing technical standards and accountability frameworks. Cluster coordination typically establishes technical working groups developing sector-specific guidance on well construction, water quality, technology selection, and monitoring ensuring response quality and consistency across implementing organizations. Information management systems track interventions geographically (4W mapping: who, what, where, when) enabling gap identification, response optimization, and accountability to affected populations and donors. Government involvement through designated line ministry (typically water resources or public works) provides policy direction, technical standards, permit oversight, and long-term sustainability planning ensuring emergency responses integrate into national water sector development rather than creating parallel systems undermining government capacity and sustainability.

Monitoring and Evaluation Framework:

Output Indicators:

• Infrastructure quantity: number of wells constructed, rehabilitated, operational

• Population coverage: persons with access <500m distance, <30 minute collection time

• Water quantity: average daily per capita supply (target 15-20 L minimum)

• Construction quality: compliance with technical standards (% meeting specifications)

• Timeline performance: construction time vs plan, population coverage rate

• Cost efficiency: cost per well, per person served, vs plan and benchmarks

Outcome Indicators:

• Water quality: % sources meeting microbiological standards, chlorine residual presence

• Functionality: % wells operational (target >80% at 3-month post-construction)

• Utilization: actual vs designed use, user satisfaction surveys

• Maintenance capacity: presence of trained caretakers, spare parts availability

• Financial sustainability: cost recovery rates, operations fund adequacy

• Gender and equity: female participation in committees, vulnerable group access

Impact Indicators:

• Public health: waterborne disease incidence (diarrhea, cholera, typhoid)

• Hygiene practices: handwashing at critical times, safe food preparation

• Time savings: hours per week saved from reduced collection distances

• School attendance: particularly girls previously missing school for water collection

• Economic impacts: productive time gained, reduced healthcare costs

• Dignity and wellbeing: satisfaction, reduced conflict over water access

Data Collection Methods:

• Routine monitoring: operations logs, flow measurements, water quality testing results

• Surveys: household surveys, facility assessments, key informant interviews

• Community feedback: complaints mechanisms, community meetings, suggestion boxes

• Remote sensing: satellite imagery, mobile data collection, GPS mapping

• Post-distribution monitoring: follow-up assessments 3, 6, 12 months post-construction

• Evaluation studies: baseline-endline surveys, control-comparison analysis, cost-effectiveness analysis

Conclusions and Best Practice Recommendations

Emergency water well development constitutes critical life-saving intervention in disaster contexts enabling rapid restoration of safe water supply to affected populations preventing disease outbreaks, reducing mortality, and supporting recovery. Effective responses balance speed of deployment against technical quality and sustainability through appropriate technology selection matching hydrogeological conditions and institutional capacity, adherence to technical and water quality standards ensuring public health protection, community engagement securing social acceptance and local ownership, and sustainability planning establishing operations and maintenance arrangements supporting long-term functionality beyond emergency phase. Experience from major disaster responses worldwide demonstrates that well-planned, technically sound, and community-engaged water supply programs achieve high rates of success with >80% functionality years post-construction, while rushed implementations lacking quality assurance, community consultation, or sustainability planning suffer premature failures requiring costly rehabilitation or abandonment within 1-2 years.

Key success factors include preparedness investments enabling rapid mobilization through pre-positioning equipment, framework agreements with drilling contractors, trained personnel, and contingency plans activated immediately post-disaster; hydrogeological assessment informing rational site selection and technology matching reducing drilling failures and improving yields; technical standards and quality assurance through design review, construction supervision, and completion testing ensuring infrastructure quality and longevity; appropriate technology selection balancing community preference, maintenance capacity, and lifecycle costs rather than imposing external solutions; community participation in site selection, technology choice, and management arrangements securing ownership and social sustainability; coordination mechanisms through WASH Cluster or equivalent ensuring information sharing, response quality, and avoiding duplication; and transition planning integrating emergency supplies into government systems or permanent infrastructure supporting long-term sustainability beyond humanitarian phase.

Essential Best Practice Recommendations

1. Preparedness and Planning:

• Develop emergency water supply contingency plans including source inventories, equipment needs, response procedures

• Pre-position critical equipment (drilling rigs, pumps, treatment systems) or establish standby agreements

• Maintain roster of trained personnel (engineers, hydrogeologists, drilling supervisors, pump mechanics)

• Conduct hydrogeological assessments in disaster-prone areas mapping groundwater resources

• Stockpile water quality testing supplies, chlorination chemicals, and emergency distribution equipment

2. Rapid Assessment and Response Planning:

• Deploy assessment teams within 24-48 hours documenting infrastructure damage and priority needs

• Utilize standardized assessment tools (WHO, Sphere) ensuring systematic coverage

• Involve hydrogeologists in assessment identifying appropriate groundwater development sites

• Develop response strategy balancing immediate trucking with medium-term source development

• Establish coordination mechanisms (WASH Cluster) aligning multiple responding agencies

3. Technology Selection and Design:

• Match well technology to hydrogeological conditions (depth, yield, geology, water quality)

• Consider institutional capacity and sustainability in technology selection (handpumps vs motorized)

• Apply technical standards ensuring sanitary protection and construction quality

• Design for climate resilience (flood protection, drought reliability, multiple sources)

• Balance initial costs against lifecycle costs including operations, maintenance, replacement

4. Construction Quality and Supervision:

• Engage qualified drilling contractors with appropriate equipment and experience

• Provide clear technical specifications and construction standards

• Implement construction supervision throughout drilling, completion, and testing phases

• Conduct thorough well development achieving design yields and acceptable water quality

• Document construction through detailed logs, test results, GPS coordinates, photographs

5. Water Quality Assurance:

• Test all sources before use for microbiological and chemical parameters

• Implement chlorination for microbiologically unsafe sources or distribution contamination risks

• Monitor water quality regularly (daily chlorine residual, weekly microbiology)

• Train operators and community members in water quality testing and interpretation

• Establish laboratory capacity or partnerships ensuring timely analysis

6. Community Engagement and Ownership:

• Consult communities on site selection, technology choices, management preferences

• Establish water committees with representative membership including women

• Train community caretakers in operations, routine maintenance, minor repairs

• Develop financial mechanisms (water fees, subsidies) ensuring operating cost coverage

• Link hygiene promotion with water supply improvements maximizing health benefits

7. Sustainability Planning:

• Establish clear management responsibility (community, contractor, utility) before handover

• Provide comprehensive training in operations, maintenance, financial management

• Ensure spare parts availability through local suppliers or stockpiles

• Develop preventive maintenance schedules and ensure operator capacity to implement

• Plan transition from emergency to development programming integrating into government systems

8. Monitoring, Learning, and Adaptation:

• Implement monitoring systems tracking coverage, water quality, functionality, user satisfaction

• Conduct post-construction follow-up identifying problems and enabling corrective action

• Document lessons learned through project reviews and evaluations

• Share information through coordination mechanisms and technical communities of practice

• Adapt approaches based on experience, local conditions, and emerging best practices

Looking forward, climate change increases disaster frequency and intensity requiring enhanced preparedness and resilient infrastructure capable of withstanding extreme events while ensuring reliable supply during extended droughts or recovery from floods, earthquakes, or storms. Technology innovation in drilling methods, pumping systems, treatment technologies, and monitoring tools creates opportunities for improved performance, cost reduction, and sustainability, with solar-powered systems, mobile treatment units, smart sensors, and digital management platforms transforming capabilities compared to even decade ago. Capacity strengthening of national and local institutions including government water authorities, private drilling sectors, technical training institutions, and community organizations proves essential for sustainable disaster risk reduction and emergency response, with investments in pre-disaster capacity building yielding substantial returns through improved preparedness, faster response, and more sustainable recovery outcomes serving affected populations better while reducing overall humanitarian costs and suffering associated with water insecurity in disaster contexts worldwide.

References and Technical Resources:

1. WHO/UNECE. Guidance on Water Supply and Sanitation In Extreme Weather Events.

https://unece.org/sites/default/files/2021-01/WHOGuidanceFVLR.pdf

2. Global WASH Network. Compendium of Water Supply Technologies in Emergencies.

https://www.washnet.de/wp-content/uploads/2021/09/GWN_Emergency-Water-Compendium_2021_new.pdf

3. US Environmental Protection Agency. Planning for an Emergency Drinking Water Supply.

https://www.epa.gov/sites/default/files/2015-03/documents/planning_for_an_emergency_drinking_water_supply.pdf

4. Reed, R.A. & Shaw, R.J. Emergency Water Supply - Livestock Emergency Guidelines and Standards.

https://www.livestock-emergency.net/userfiles/file/water-supply/Reed-Shaw.pdf

5. Centers for Disease Control and Prevention. Emergency Water Supply Planning Guide for Hospitals and Healthcare Facilities.

https://www.cdc.gov/water-emergency/media/pdfs/2024/07/emergency-water-supply-planning-guide-2019-508.pdf

6. Sphere Project. The Sphere Handbook: Humanitarian Charter and Minimum Standards in Humanitarian Response (Bahasa Indonesia).

https://spherestandards.org/wp-content/uploads/Sphere-Handbook-2018-Bahasa-Indonesia.pdf

7. World Health Organization. (2017). Guidelines for Drinking-water Quality: Fourth Edition Incorporating the First Addendum.

https://www.who.int/publications/i/item/9789241549950

8. UNICEF. (2019). Water Handbook for Small Communities: Guidelines for Local Governments and Communities.

https://www.unicef.org/wash/water

9. International Federation of Red Cross and Red Crescent Societies. Public Health Guide for Emergencies.

https://www.ifrc.org/health-and-care

10. UNHCR. WASH Manual for Refugee Settings.

https://www.unhcr.org/water-and-energy

11. Oxfam. Water Supply and Sanitation in Emergencies (Technical Briefs).

https://policy-practice.oxfam.org/resources/water-supply-and-sanitation-technical-briefs-620847/

12. World Bank. Emergency Water Supply, Sanitation and Hygiene (WASH) Interventions in Emergency Settings.

https://www.worldbank.org/en/topic/water

13. WEDC Loughborough University. Technical Briefs on Emergency Water Supply.

https://wedc-knowledge.lboro.ac.uk/

14. Global WASH Cluster. Emergency Response Guidance and Tools.

https://washcluster.net/resources

15. WHO. (2013). Guidance on Water Supply and Sanitation in Extreme Weather Events.

https://cawater-info.net/library/eng/guidance_on_water_supply_sanitation_en.pdf

Expert Support for Emergency Water Supply Planning and Implementation

SUPRA International provides comprehensive technical assistance for emergency water supply programs including disaster preparedness planning, rapid needs assessment, hydrogeological surveys and well siting, drilling contractor management, water quality testing and treatment system design, pumping system selection and installation, operations and maintenance training, community engagement and institutional development, monitoring and evaluation frameworks, and technical backstopping support throughout emergency response and recovery phases. Our multidisciplinary team combines water resources engineering, hydrogeology, public health, and humanitarian program management expertise serving government disaster management agencies, international humanitarian organizations, bilateral donors, and development institutions implementing emergency WASH interventions worldwide.

Planning emergency water supply interventions or strengthening disaster preparedness capacity?

Contact our emergency WASH specialists for expert technical guidance and implementation support

Share:

If you face challenges in water, waste, or energy, whether it is system reliability, regulatory compliance, efficiency, or cost control, SUPRA is here to support you. When you connect with us, our experts will have a detailed discussion to understand your specific needs and determine which phase of the full-lifecycle delivery model fits your project best.