Environmental Site Assessment (ESA) Phase 1, 2, and 3: Technical Framework for Due Diligence and Contamination Management

Environmental Site Assessment (ESA) Phase 1, 2, and 3: Technical Framework for Due Diligence and Contamination Management

Reading Time: 52 minutes

Key Highlights

• Regulatory Integration: Environmental Site Assessment in Indonesia integrates ASTM E1527 international standards with KLHK (Ministry of Environment and Forestry) regulatory framework including AMDAL requirements, creating comprehensive environmental due diligence approach for property transactions and development projects

• Phase 1 Scope: Preliminary assessment involves desktop studies, site reconnaissance, historical records review, interviews with stakeholders, and regulatory database searches to identify Recognized Environmental Conditions (RECs) without physical sampling, typically completed within 2-3 weeks at costs ranging IDR 25-65 million depending on site complexity

• Phase 2 Investigation: Intrusive site investigation includes soil boring, groundwater monitoring well installation, laboratory analysis of samples for contaminants, and risk assessment comparing results against Indonesian quality standards (SNI) and international benchmarks like Dutch Quality Standards for industrial site use

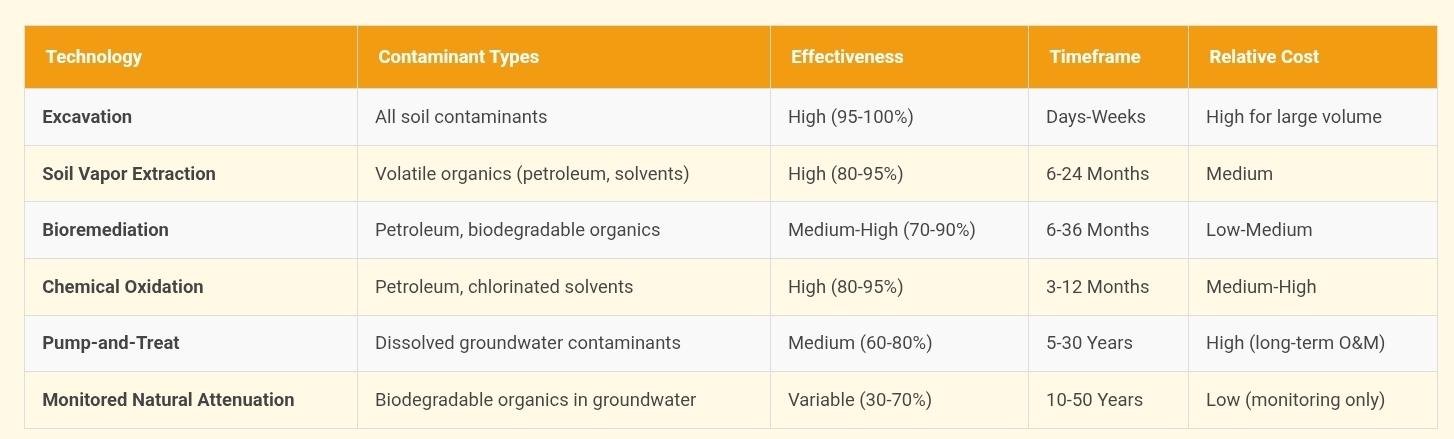

• Phase 3 Remediation: Active contamination cleanup employs remediation techniques including soil excavation and disposal, bioremediation using microorganisms, soil vapor extraction systems, groundwater pump-and-treat, chemical oxidation, and monitored natural attenuation with regulatory closure procedures ensuring environmental compliance

Executive Summary

Environmental Site Assessment constitutes systematic process evaluating potential or actual environmental contamination liability associated with commercial and industrial properties through phased investigation approach progressing from preliminary research to intrusive sampling and eventual remediation when contamination identified. Indonesian context integrates international best practices primarily following American Society for Testing and Materials (ASTM) Standard E1527 while incorporating domestic regulatory requirements administered by Ministry of Environment and Forestry (KLHK) including Environmental Impact Assessment (AMDAL) framework and national quality standards (SNI) for soil and groundwater contamination thresholds. This comprehensive framework serves property buyers, sellers, developers, financial institutions, and industrial operators requiring environmental due diligence for transaction support, liability protection, development planning, and regulatory compliance purposes.

Phase 1 Environmental Site Assessment represents non-intrusive preliminary investigation identifying potential environmental concerns through historical research, site inspection, interviews, and regulatory database review without physical sampling or laboratory analysis. Qualified environmental professionals conduct comprehensive review of property history, current operations, surrounding land uses, regulatory compliance records, and physical site conditions to identify Recognized Environmental Conditions (RECs) representing potential contamination sources requiring further investigation. Indonesian Phase 1 ESA incorporates ASTM E1527 standard adapted to local context including review of KLHK regulatory databases, historical land use records, industrial permits, waste management documentation, and compliance with environmental management plans (UKL-UPL) or AMDAL documents depending on project scale and sector. Typical Phase 1 assessment requires 2-3 weeks completion timeline with costs ranging IDR 25-65 million varying by site complexity, accessibility, historical data availability, and scope requirements.

Phase 2 ESA follows when Phase 1 identifies RECs warranting confirmation through physical investigation, involving intrusive sampling of soil, groundwater, surface water, soil vapor, or building materials to quantify contamination presence and extent. Field investigation employs drilling techniques installing soil borings to depths typically 5 meters below ground level with sampling at 1-meter intervals or wherever stratum changes or visual contamination indicators observed, plus monitoring well installation for groundwater assessment following industry protocols. Collected samples undergo laboratory analysis by ISO 17025 accredited facilities testing for chemical and metal contaminants specific to identified RECs, with results compared against Indonesian SNI standards, Dutch Quality Standards commonly referenced for industrial sites, or international criteria depending on project requirements and intended land use. Phase 2 generates Conceptual Site Model documenting contamination sources, migration pathways, exposure receptors, and risk assessment determining whether contamination levels present unacceptable risks requiring remediation or management measures.

Phase 3 ESA implements remediation addressing confirmed contamination through cleanup strategies selected based on contaminant type, extent, site characteristics, intended use, regulatory requirements, cost considerations, and project timeline. Remediation techniques span excavation and off-site disposal of contaminated soil (most common approach for limited contamination), in-situ bioremediation employing microorganisms degrading organic contaminants, soil vapor extraction removing volatile organic compounds, groundwater pump-and-treat systems, chemical oxidation breaking down contaminants, solidification/stabilization immobilizing contaminants, and monitored natural attenuation for sites where natural processes achieve cleanup objectives within acceptable timeframes. Indonesian regulatory framework requires remediation achieving environmental quality standards with documentation submitted to KLHK or provincial environmental agencies demonstrating cleanup effectiveness and site closure readiness, typically involving post-remediation sampling confirming contaminant reduction below applicable thresholds and obtaining official closure letters permitting unrestricted site use or implementing land use restrictions if residual contamination remains.

Environmental Site Assessment business context spans property acquisition due diligence where buyers require environmental condition understanding before purchase commitments, financing requirements where lenders mandate ESA documentation protecting collateral value, development planning identifying contamination constraints affecting project feasibility and costs, regulatory compliance demonstrating environmental management pursuant to AMDAL or operational permits, liability protection establishing "innocent landowner" defense limiting cleanup responsibility for historical contamination, and transaction negotiations where ESA findings inform purchase price adjustments or seller remediation obligations. Indonesian regulatory environment increasingly emphasizes environmental accountability through strengthened enforcement, public disclosure requirements, and financial liability provisions creating substantial business risk from undisclosed contamination, making comprehensive ESA practice essential risk management tool for property stakeholders across commercial, industrial, and institutional sectors throughout Indonesian archipelago.

Phase 1 Environmental Site Assessment: Preliminary Investigation Framework

Phase 1 Environmental Site Assessment constitutes preliminary, non-invasive evaluation of property environmental condition through systematic review of historical uses, current operations, regulatory compliance status, and physical site characteristics identifying potential contamination sources without conducting physical sampling or laboratory analysis. Assessment objectives include determining whether Recognized Environmental Conditions (RECs) exist on property warranting further investigation through Phase 2 intrusive sampling, establishing baseline environmental condition understanding for transaction due diligence, identifying potential environmental liabilities affecting property value or development feasibility, and documenting environmental compliance status relative to applicable Indonesian regulations including KLHK requirements and AMDAL framework provisions.

Qualified Environmental Professional (EP) conducts Phase 1 ESA meeting specific credentials including relevant educational background (environmental engineering, geology, environmental science), professional experience conducting environmental assessments, and familiarity with applicable regulatory frameworks and assessment methodologies. Indonesian context may involve Environmental Management Expert (Ahli Lingkungan) certified by Ministry of Environment and Forestry with AMDAL preparation credentials, though international consultants conducting ESA for multinational clients or financing institutions typically employ professionals meeting ASTM E1527 qualification standards ensuring consistency with global due diligence practices. Assessment scope follows structured methodology encompassing four primary components: records review, site reconnaissance, interviews, and report preparation synthesizing findings into conclusions about environmental condition and recommendations for additional investigation or risk management measures.

Phase 1 ESA Core Components and Activities:

Records Review - Historical and Regulatory Documentation:

• Property ownership history and chain of title documentation

• Historical land use records including aerial photographs, topographic maps, city directories

• Previous environmental assessments or contamination investigations

• Industrial permits, environmental licenses, operational approvals

• AMDAL documents (KA-ANDAL, ANDAL, RKL-RPL) or UKL-UPL environmental management plans

• Waste management records including B3 hazardous waste manifests, disposal documentation

• Regulatory compliance reports, inspection records, enforcement actions, violations

• Environmental monitoring data from operational activities

• Underground storage tank registrations, removal reports, leak investigations

• Asbestos surveys, lead paint assessments, mold investigations for existing structures

• Regulatory database searches identifying contaminated sites, active facilities, closed operations

Site Reconnaissance - Physical Property Inspection:

• Current land use observation and operational activity documentation

• Building inspection including hazardous material identification (asbestos, lead paint, PCBs)

• Storage area review identifying chemicals, petroleum products, hazardous materials

• Waste management practices observation including storage, handling, disposal procedures

• Underground storage tank indicators including fill ports, vent pipes, dispenser islands

• Staining, stressed vegetation, unusual odors indicating potential contamination

• Drainage patterns, water bodies, wetlands, environmentally sensitive areas

• Adjacent property uses potentially affecting subject property through contamination migration

• Site security, access control, unauthorized dumping evidence

• Photographic documentation of site conditions, potential concerns, surrounding context

Interviews - Stakeholder Information Gathering:

• Current property owner interview regarding operational history, environmental incidents, known concerns

• Site manager, facility operators interviews about daily activities, chemical usage, waste generation

• Maintenance personnel discussions about underground infrastructure, past repairs, unusual observations

• Previous owners or operators if accessible providing historical perspective

• Adjacent property owners regarding potential off-site contamination sources

• Local government environmental officials about known contamination, enforcement history

• Community members if appropriate regarding historical site uses, environmental concerns

Report Preparation - Findings Documentation and Conclusions:

• Executive summary of assessment scope, methodology, key findings, conclusions

• Site description including location, size, topography, geology, hydrogeology

• Historical use summary documenting property use evolution and contamination risk changes

• Current operations description including processes, chemical usage, waste generation

• Regulatory status review of compliance, permits, violations, ongoing issues

• Site reconnaissance findings with photographic documentation

• Adjacent property assessment identifying potential off-site concerns

• Recognized Environmental Conditions identification and description

• Conclusions and recommendations including Phase 2 ESA necessity determination

• Qualifications of environmental professional conducting assessment

• Limitations and exceptions acknowledging assessment scope boundaries

Recognized Environmental Conditions (RECs) represent presence or likely presence of hazardous substances or petroleum products in property environment due to release, threat of release, or disposal occurring under conditions suggesting potential environmental contamination. RECs identification triggers recommendation for Phase 2 intrusive investigation confirming contamination presence and quantifying extent. Common RECs in Indonesian industrial context include underground storage tanks (current or historical) potentially leaking petroleum products, industrial chemical storage and handling areas with staining or spillage evidence, waste disposal locations including historical landfills or dumping areas, manufacturing processes involving hazardous materials potentially releasing contaminants to soil or groundwater, transformer equipment containing PCBs, building materials including asbestos or lead paint, and adjacent contaminated properties where migration pathways potentially affect subject property through groundwater transport or vapor intrusion mechanisms.

Indonesian regulatory database review encompasses Ministry of Environment and Forestry records identifying permitted facilities, enforcement actions, contaminated sites requiring remediation, and hazardous waste generators or transporters. Provincial and municipal environmental agencies maintain additional records including local permits, inspection reports, and complaint documentation. National Agency for Hazardous Waste Management (BADAN or relevant KLHK directorate) tracks hazardous waste generation, transport, treatment, and disposal activities through manifest system requiring documentation. Phase 1 ESA includes review of these regulatory databases within appropriate search distances (typically 0.5-1.0 kilometer radius for most databases, extending to several kilometers for major contaminated sites or groundwater contamination sources) identifying facilities potentially affecting subject property through direct contamination or off-site migration.

Phase 1 ESA Checklist for Indonesian Properties

Pre-Assessment Planning:

☐ Define assessment scope and objectives with client

☐ Obtain site access authorization from property owner

☐ Review available documentation provided by client

☐ Identify environmental professionals and qualifications

☐ Prepare site visit checklist and data collection forms

☐ Schedule interviews with relevant stakeholders

Records Review Documentation:

☐ Property ownership and title search records

☐ Historical aerial photographs (minimum 10-year intervals back to 1950s if available)

☐ Topographic maps, city directories, Sanborn fire insurance maps

☐ AMDAL documents (KA-ANDAL, ANDAL, RKL-RPL) or UKL-UPL

☐ Environmental permits and licenses from KLHK, provincial, municipal agencies

☐ Industrial permits, operational approvals, technical permits

☐ Hazardous waste manifests and disposal records

☐ Underground storage tank records (installation, testing, removal)

☐ Previous environmental assessments or investigations

☐ Regulatory compliance reports and monitoring data

☐ Enforcement actions, violations, corrective action orders

☐ Building permits, construction records, renovation documentation

Site Reconnaissance Checklist:

☐ Document current property use and operational activities

☐ Inspect buildings for hazardous materials (asbestos, lead paint, PCBs)

☐ Identify chemical storage areas and hazardous material inventories

☐ Review waste management practices and storage areas

☐ Search for underground storage tank indicators (fill ports, vents)

☐ Document staining, stressed vegetation, unusual odors

☐ Observe drainage patterns, surface water features, wetlands

☐ Assess adjacent property uses and potential off-site concerns

☐ Take comprehensive photographs documenting site conditions

☐ Sketch site layout showing buildings, operations, potential concern areas

☐ Note any limitations on site access or visibility

Interview Questions Framework:

☐ Length of ownership/operation at property

☐ Historical uses and operational changes over time

☐ Current processes, chemicals used, waste generated

☐ Known environmental incidents, spills, releases

☐ Underground storage tank history (installation, removal, leaks)

☐ Waste disposal practices and documentation

☐ Environmental compliance issues, violations, enforcement actions

☐ Previous environmental assessments or investigations

☐ Hazardous building materials (asbestos, lead, PCBs)

☐ Adjacent property concerns or contamination awareness

☐ Maintenance activities, repairs, underground infrastructure work

Report Components Checklist:

☐ Executive summary with key findings and conclusions

☐ Introduction describing assessment purpose and scope

☐ Site description including location, setting, physical characteristics

☐ Historical use summary with timeline of activities

☐ Current operations description

☐ Regulatory compliance status review

☐ Site reconnaissance findings with photo documentation

☐ Adjacent property assessment

☐ Recognized Environmental Conditions identification

☐ Conclusions and recommendations

☐ Environmental professional qualifications

☐ Limitations and exceptions statement

☐ Appendices with supporting documentation, photographs, records

Phase 1 ESA deliverable comprises comprehensive written report documenting assessment methodology, findings, and conclusions typically ranging 30-80 pages depending on site complexity and historical data volume. Report follows standardized format ensuring consistent presentation facilitating review by property stakeholders, lenders, regulators, and subsequent environmental professionals potentially conducting Phase 2 investigations. Executive summary provides concise overview enabling non-technical readers understand key findings and recommendations within 2-3 pages. Main report body presents detailed findings supporting conclusions with appropriate documentation including historical records, regulatory database results, interview summaries, and site reconnaissance observations. Photographic documentation illustrates current site conditions and potential environmental concerns. Appendices compile supporting materials including regulatory database reports, historical documents, and environmental professional credentials.

Phase 2 Environmental Site Assessment: Intrusive Investigation and Sampling

Phase 2 Environmental Site Assessment conducts intrusive investigation through physical sampling and laboratory analysis confirming contamination presence, quantifying concentrations, delineating extent, and assessing risks identified during Phase 1 assessment as Recognized Environmental Conditions requiring verification. Investigation employs drilling techniques, monitoring well installation, sample collection following strict protocols, accredited laboratory analysis, data interpretation, risk assessment, and reporting documenting contamination nature, extent, and recommendations for remediation, risk management, or no further action depending on findings. Phase 2 scope design bases on Phase 1 RECs, site-specific characteristics including geology and hydrogeology, potential contaminants of concern based on historical uses, and investigation objectives addressing client due diligence requirements, regulatory compliance needs, or development planning considerations.

Conceptual Site Model (CSM) development precedes field investigation, documenting contamination sources, release mechanisms, transport pathways, exposure routes, and potential receptors creating framework guiding sampling strategy design. CSM identifies potential contaminants of concern based on industrial processes, chemical usage, historical releases, or adjacent property impacts. For example, former gasoline service station CSM identifies underground storage tanks as contamination source, petroleum hydrocarbons (BTEX, TPH) as contaminants of concern, vadose zone and groundwater as affected media, lateral and vertical migration pathways, and human receptors through potential drinking water well usage or construction worker exposure during excavation. CSM evolves as investigation progresses, refined with field observations and analytical results informing subsequent sampling activities until contamination adequately characterized for decision-making purposes.

Phase 2 ESA Investigation Components:

Soil Investigation - Subsurface Sampling:

• Drilling methods selection (hollow-stem auger, solid-stem auger, direct push technology)

• Boring locations targeting identified RECs and downgradient areas

• Boring depths typically 5 meters below ground level or to groundwater table

• Sample intervals at 1-meter depth increments or lithologic unit changes

• Field screening using photoionization detector (PID), visual observation, odor

• Sample collection in laboratory-provided containers following chain-of-custody

• Soil description and logging documenting lithology, moisture, color, texture

• Decontamination procedures for drilling equipment between boring locations

• Boring abandonment following proper protocols preventing cross-contamination

• Survey of boring locations determining coordinates and elevations

Groundwater Investigation - Monitoring Well Installation:

• Well installation at strategic locations based on CSM and site hydrogeology

• Well construction including borehole drilling, casing and screen installation

• Screen interval placement typically spanning water table (2 meters above to 3 meters below)

• Filter pack placement around screen interval using clean silica sand

• Annular seal above filter pack preventing surface water infiltration

• Surface completion with flush-mount or above-ground protective casing

• Well development removing drilling fluids and fines improving formation communication

• Water level measurement establishing hydraulic gradient and flow direction

• Low-flow sampling technique minimizing sample disturbance and turbidity

• Field parameter measurement (pH, temperature, conductivity, dissolved oxygen)

• Sample collection following chain-of-custody with appropriate preservation

Laboratory Analysis - Sample Testing:

• ISO 17025 accredited laboratory selection ensuring quality standards

• Analytical methods appropriate for contaminants of concern and matrix

• Petroleum hydrocarbons analysis (TPH, BTEX, PAHs) for petroleum sites

• Volatile organic compounds (VOCs) for industrial solvent contamination

• Semi-volatile organic compounds (SVOCs) for historical industrial operations

• Metals analysis (arsenic, lead, cadmium, chromium, mercury) for industrial sites

• Pesticides/herbicides for agricultural properties

• PCBs for sites with electrical transformers or equipment

• Quality assurance/quality control including duplicates, blanks, matrix spikes

• Reporting limits appropriate for comparison with applicable standards

Data Interpretation and Risk Assessment:

• Comparison of analytical results with Indonesian SNI standards

• Reference to Dutch Quality Standards (intervention values) for industrial sites

• International criteria application (WHO, USEPA, other) as appropriate

• Spatial analysis identifying contamination distribution patterns

• Contaminant concentration mapping (plan view and cross-sections)

• Exposure pathway evaluation (ingestion, inhalation, dermal contact)

• Human health risk assessment using conservative exposure assumptions

• Ecological risk assessment for environmental receptors

• Recommendations for remediation, management, or no further action

• Regulatory notification requirements if thresholds exceeded

Soil sampling employs drilling rigs or direct push technology advancing boreholes to target depths recovering continuous or discrete samples for visual observation, field screening, and laboratory analysis. Drilling methods selection depends on subsurface conditions (soft sediments versus consolidated materials), target depth, required sample quality, and budget constraints. Hollow-stem auger drilling proves most common for depths under 15 meters in unconsolidated sediments, allowing sample collection through hollow auger center without borehole collapse. Direct push technology (DPT) using hydraulic pressure advances sampling tools rapidly in soft sediments cost-effectively for reconnaissance investigations, though limited to shallow depths and unconsolidated materials. Sample intervals typically occur at 1-meter depth increments plus additional sampling where visual, olfactory, or field instrument readings indicate contamination, ensuring adequate characterization without excessive sample counts inflating costs unnecessarily.

Groundwater monitoring wells enable groundwater quality assessment, water level measurement determining flow direction and hydraulic gradient, and long-term monitoring tracking contamination changes over time. Well construction follows standardized procedures ensuring representative samples and preventing cross-contamination between aquifers. Borehole drilling extends below water table allowing screen interval installation spanning typical water level fluctuation range (typically 2 meters above static water level to 3 meters below). Well screen selection considers formation characteristics and target contaminants, with slotted PVC screen most common for standard groundwater monitoring. Filter pack placement around screen consists of clean silica sand sized preventing formation material entry while maintaining hydraulic communication. Bentonite seal above filter pack prevents surface water infiltration potentially biasing samples. Surface completion protects well integrity using locking cap preventing tampering and contamination.

Phase 2 ESA Sampling Protocol and QA/QC Requirements

Soil Sampling Procedures:

Sample Collection:

• Use clean sampling tools decontaminated between locations

• Collect samples in laboratory-provided containers with appropriate preservation

• VOC samples collected first in 40mL vials with no headspace

• Fill containers completely avoiding air spaces and contamination

• Label containers with sample ID, date, time, collector initials

• Document samples on chain-of-custody form with signatures

Field Documentation:

• Record boring/sample location with GPS coordinates

• Document depth interval for each sample

• Describe soil characteristics (color, texture, moisture, odor)

• Note any visual contamination indicators

• Record PID readings for volatile organic screening

• Photograph sampling activities and samples

Groundwater Sampling Procedures:

Well Development:

• Allow minimum 48-hour stabilization period after well installation

• Purge 3-5 well casing volumes removing drilling fluids and sediment

• Monitor turbidity decrease to <50 NTU before sampling

• Dispose of purge water appropriately (containerization if contaminated)

Sample Collection:

• Measure static water level before sampling

• Employ low-flow sampling technique minimizing drawdown

• Monitor field parameters (pH, temperature, conductivity, DO) until stable

• Collect samples in laboratory containers with appropriate preservation

• Maintain sample temperature at 4°C during transport

• Deliver samples to laboratory within holding time requirements

Quality Assurance/Quality Control (QA/QC):

Field QC Samples (minimum 10% of total samples):

• Field duplicates: Collect replicate samples assessing sampling precision

• Equipment blanks: Rinse sampling equipment documenting decontamination effectiveness

• Trip blanks: VOC vial accompanying samples detecting transport contamination

• Field blanks: Distilled water exposed to field conditions assessing ambient contamination

Laboratory QC Samples:

• Method blanks: Analyze blank matrix detecting laboratory contamination

• Matrix spikes: Add known contaminant concentration assessing recovery

• Laboratory control samples: Analyze certified reference materials verifying method accuracy

• Duplicate analysis: Reanalyze samples assessing analytical precision

• Surrogate standards: Add compounds monitoring analytical performance

Data Validation and Usability:

• Review laboratory QC data against acceptance criteria

• Verify reporting limits appropriate for comparison standards

• Assess field QC sample results for anomalies

• Identify qualified data requiring footnotes or exclusion

• Document data validation findings in assessment report

• Retain laboratory analytical reports and QC data in appendices

Laboratory selection requires ISO 17025 accreditation ensuring quality management systems, method validation, and proficiency testing demonstrating analytical capability. Indonesian context may utilize domestic accredited laboratories (registered with KLHK) for standard parameters or international laboratories for specialized analyses unavailable locally. Analytical methods selection considers contaminants of concern, sample matrix, required detection limits, and applicable standards. Standard analytical methods include gas chromatography (GC) for volatile organics, gas chromatography-mass spectrometry (GC-MS) providing compound-specific identification, inductively coupled plasma mass spectrometry (ICP-MS) for metals at low concentrations, and high-performance liquid chromatography (HPLC) for certain organic compounds. Quality assurance/quality control protocols including method blanks, matrix spikes, laboratory control samples, and duplicate analyses ensure data reliability essential for decision-making.

Phase 2 report presents investigation findings including summary of Phase 1 RECs, field investigation methodology, boring logs and well construction details, analytical results in tabular and graphical formats, comparison with applicable standards, risk assessment conclusions, and recommendations for remediation, additional investigation, risk management, or site closure. Comparison standards in Indonesian context include SNI quality standards where established, Dutch Quality Standards (intervention values) commonly referenced for industrial site contamination, or international criteria (WHO drinking water guidelines, USEPA regional screening levels) depending on project requirements and intended land use. Risk assessment evaluates exposure pathways based on current and reasonably anticipated future land use, with industrial/commercial properties typically assessed under occupational exposure scenarios while residential development requires more stringent residential exposure assumptions including child receptors.

Phase 3 Environmental Site Assessment: Remediation Planning and Implementation

Phase 3 Environmental Site Assessment addresses confirmed contamination through remediation planning, implementation, and verification achieving environmental quality standards permitting unrestricted site use or implementing institutional controls managing residual contamination under risk-based framework. Remediation scope bases on Phase 2 characterization data including contaminant types, concentrations, spatial distribution, affected media (soil, groundwater, vapor), and identified exposure pathways requiring elimination or management. Remedial approach selection considers multiple factors including contamination extent and complexity, contaminant properties affecting treatment effectiveness, site characteristics constraining technology application, regulatory cleanup standards and approval processes, cost and schedule requirements, stakeholder preferences, and intended future land use influencing acceptable residual contamination levels.

Remedial Action Plan (RAP) development precedes field implementation, documenting remediation objectives, selected technologies, implementation procedures, performance monitoring, contingency measures, health and safety protocols, and regulatory approval requirements. RAP preparation involves remedial alternatives analysis evaluating feasibility, effectiveness, implementability, cost, and timeframe for technology options appropriate to site-specific conditions. Common remediation techniques applicable Indonesian context span excavation and off-site disposal (most direct approach for limited soil contamination), soil vapor extraction removing volatile compounds from unsaturated zone, bioremediation employing microorganisms degrading organic contaminants, chemical oxidation destroying contaminants through oxidant injection, solidification/stabilization immobilizing contaminants reducing mobility, phytoremediation using vegetation extracting or degrading contaminants, groundwater extraction and treatment removing dissolved contamination, and monitored natural attenuation relying on natural processes where appropriate conditions exist.

Phase 3 ESA Remediation Technologies Overview:

Soil Excavation and Disposal:

• Most common technique for limited volume contamination (<500 cubic meters)

• Excavation to confirmed clean soil beneath contamination zone

• Confirmation sampling from excavation sidewalls and base verifying removal

• Off-site disposal at licensed hazardous or non-hazardous waste landfill

• Clean backfill placement and compaction restoring site grade

• Advantages: Rapid implementation, permanent removal, regulatory acceptance

• Limitations: Higher cost for large volumes, disposal facility capacity constraints, contaminated groundwater remains

• Typical timeline: 1-5 days field work depending on volume

• Estimated cost: IDR 500,000-2,000,000 per cubic meter including disposal

Soil Vapor Extraction (SVE):

• Vacuum application to unsaturated zone removing volatile contaminants

• Vapor extraction wells installed in contamination zone

• Blower/vacuum system inducing air flow through soil

• Vapor treatment using activated carbon or catalytic oxidation

• Applicable to petroleum hydrocarbons, solvents (BTEX, chlorinated VOCs)

• Best suited shallow (<10 meters) contamination in permeable sandy soils

• Monitoring includes vapor concentrations, flow rates, cumulative mass removed

• Advantages: In-situ treatment, cost-effective for large volumes, minimal site disruption

• Limitations: Requires adequate soil permeability, extended timeframes, utility costs

• Typical timeline: 6-24 months operation until cleanup objectives achieved

• Estimated cost: IDR 200-500 million capital, IDR 10-30 million monthly O&M

Bioremediation:

• Microorganisms degrading organic contaminants to innocuous byproducts

• Enhanced bioremediation adds nutrients/oxygen stimulating microbial activity

• Applicable to petroleum hydrocarbons, some solvents, explosives

• Requires aerobic conditions or anaerobic microbial populations

• Implementation through soil amendment mixing or groundwater injection

• Monitoring includes contaminant degradation, microbial populations, geochemistry

• Advantages: Natural process, cost-effective, in-situ or ex-situ application

• Limitations: Extended timeframes, site-specific effectiveness, requires favorable conditions

• Typical timeline: 6-36 months depending on contaminants and conditions

• Estimated cost: IDR 150-400 million capital, IDR 5-20 million monthly monitoring

Chemical Oxidation:

• Oxidant injection destroying contaminants through chemical reaction

• Common oxidants: hydrogen peroxide, sodium persulfate, potassium permanganate

• Applicable to petroleum hydrocarbons, chlorinated solvents, some pesticides

• Direct push injection or well installation for reagent delivery

• Rapid contaminant destruction (days to months) versus bioremediation

• Monitoring includes contaminant concentrations, oxidant presence, geochemistry

• Advantages: Rapid treatment, in-situ application, treats source zones

• Limitations: Chemical costs, potential heat generation, aquifer chemistry impacts

• Typical timeline: 3-12 months including multiple injection events

• Estimated cost: IDR 300-800 million depending on treatment volume and oxidant

Groundwater Pump-and-Treat:

• Extraction wells pumping contaminated groundwater to surface treatment

• Treatment technologies: air stripping, activated carbon, advanced oxidation

• Treated water discharge to surface water or reinjection downgradient

• Applicable to dissolved contamination in saturated zone

• Hydraulic containment preventing plume migration

• Long-term operation required for low-permeability formations

• Monitoring includes groundwater levels, concentrations, treatment efficiency

• Advantages: Proven technology, regulatory acceptance, mass removal verification

• Limitations: Extended timeframes, tailing effects, operational costs

• Typical timeline: 5-30 years depending on hydrogeology and objectives

• Estimated cost: IDR 500 million-2 billion capital, IDR 20-80 million monthly O&M

Monitored Natural Attenuation (MNA):

• Natural processes reducing contamination through dispersion, dilution, degradation

• Requires demonstration that attenuation occurring at acceptable rates

• Long-term groundwater monitoring documenting concentration trends

• Applicable where contamination poses low risk and active remediation infeasible

• Often implemented with source removal addressing high-concentration areas

• Monitoring network tracking plume extent and concentration changes

• Regulatory approval requires technical justification and stakeholder acceptance

• Advantages: Lowest cost option, natural processes, minimal site disruption

• Limitations: Extended timeframes, ongoing monitoring costs, regulatory uncertainty

• Typical timeline: 10-50 years until cleanup objectives achieved

• Estimated cost: IDR 50-150 million annual monitoring depending on network size

Indonesian regulatory framework for remediation follows KLHK guidelines requiring notification when contamination exceeds quality standards, preparation of remediation plan (similar to RAP) for approval, implementation under regulatory oversight, performance monitoring demonstrating effectiveness, and closure procedures including final sampling confirmation and issuance of environmental clearance letter permitting unrestricted use or implementing deed restrictions if residual contamination remains. Provincial and municipal environmental agencies may also participate in oversight depending on facility permitting jurisdiction. Remediation approval timeframes vary substantially based on project complexity, agency workload, and documentation completeness, though 2-6 months proves typical for straightforward projects while complex sites may require extended review periods.

Remediation implementation requires contractor selection with relevant experience and capabilities, health and safety planning protecting workers and community, quality assurance/quality control procedures ensuring effective cleanup, community engagement addressing concerns and maintaining public confidence, and adaptive management responding to unexpected conditions encountered during field work. Excavation projects typically complete within days or weeks while in-situ treatment systems may operate for months or years depending on cleanup objectives and site-specific effectiveness. Post-remediation monitoring verifies cleanup objectives achieved through confirmation sampling comparing final concentrations against applicable standards. Statistical analyses may support demonstration that remaining contamination below thresholds at required confidence levels. Final report documents remediation activities, analytical results, objectives achievement, and recommendations for site closure or long-term monitoring if institutional controls implemented.

Remediation Technology Selection Matrix

Selection Guidance:

Limited volume soil contamination (<100 m³): Excavation provides most cost-effective solution with rapid completion.

Large volume volatile contamination: Soil vapor extraction offers in-situ treatment with lower total costs than excavation.

Petroleum hydrocarbons in soil: Bioremediation effective natural treatment approach with favorable cost-benefit ratio.

Chlorinated solvent groundwater plume: Chemical oxidation combined with monitoring provides aggressive treatment.

Low-risk groundwater contamination: Monitored natural attenuation acceptable where plume stable and receptors absent.

Complex mixed contamination: Technology combination (e.g., excavation of source + bioremediation of residual) often optimal.

Indonesian Regulatory Standards and Compliance Framework

Indonesian environmental quality standards provide benchmarks comparing analytical results determining whether contamination exceeds thresholds requiring remediation or management actions. Standards encompass soil quality criteria, groundwater quality standards, and risk-based approaches for site-specific conditions not addressed by generic criteria. Ministry of Environment and Forestry (KLHK) administers national standards development and enforcement, though implementation often involves provincial environmental agencies (Dinas Lingkungan Hidup) or municipal authorities depending on facility permitting jurisdiction and contamination extent. International standards including Dutch Quality Standards (intervention values for soil and groundwater), World Health Organization drinking water guidelines, or USEPA Regional Screening Levels provide supplementary reference where Indonesian standards lack coverage for specific contaminants or exposure scenarios.

Indonesian Environmental Quality Standards Framework:

Soil Quality Standards:

• SNI standards under development for soil contamination assessment

• Dutch Quality Standards commonly referenced for industrial site assessments

• Target values: Background concentrations for pristine soil

• Intervention values: Thresholds requiring remediation action

• Site-specific risk assessment alternative when generic standards inappropriate

• Soil screening levels vary by land use (residential, commercial, industrial)

Groundwater Quality Standards:

• Government Regulation addressing water quality classification

• Class I-IV classifications based on designated beneficial uses

• Class I: Suitable for drinking water without treatment

• Class II: Drinking water with conventional treatment

• Class III: Agriculture, livestock watering

• Class IV: Industrial use, ecosystem maintenance

• Specific parameter limits for metals, organics, physical characteristics

• Background water quality consideration for naturally occurring elements

AMDAL Integration with ESA:

• Major projects require AMDAL (Environmental Impact Assessment) before development

• AMDAL documents include baseline environmental quality characterization

• Phase 1 ESA informs AMDAL baseline studies and contamination assessment

• Phase 2 sampling data supports AMDAL documentation requirements

• Remediation may require AMDAL modification or supplementary assessment

• RKL-RPL (management and monitoring plans) incorporate remediation oversight

• Post-remediation monitoring integrated with operational environmental monitoring

Regulatory Notification and Approval Requirements:

• Contamination discovery notification to KLHK or provincial agency

• Remediation plan submission describing approach, schedule, objectives

• Agency review and approval before remediation commencement

• Progress reporting during remediation implementation

• Completion report with analytical results demonstrating cleanup achievement

• Site closure letter issuance permitting unrestricted use

• Deed restrictions recording if institutional controls required

• Long-term monitoring where residual contamination managed in place

Frequently Asked Questions About Environmental Site Assessments in Indonesia

1. When is Environmental Site Assessment required for property transactions in Indonesia?

Environmental Site Assessment proves necessary for commercial and industrial property transactions where environmental contamination risk exists based on current or historical operations, lender requirements mandating ESA documentation protecting collateral value, development projects requiring AMDAL documentation including baseline environmental characterization, and due diligence purposes where buyers seek understanding of potential environmental liabilities before acquisition commitments. Financial institutions financing property purchases typically require Phase 1 ESA as standard practice for commercial/industrial properties, with Phase 2 triggered when Phase 1 identifies Recognized Environmental Conditions. Foreign investors and multinational corporations frequently require ESA following international standards (ASTM E1527) regardless of domestic legal requirements, establishing consistent environmental due diligence across global property portfolios. Indonesian regulatory framework does not explicitly mandate ESA for all transactions, though AMDAL requirements for major development projects effectively require environmental baseline assessment incorporating ESA elements.

2. How long does each ESA phase typically require for completion in Indonesian context?

Phase 1 ESA typically requires 2-3 weeks from initiation to final report delivery, though timeline varies based on site complexity, historical data availability, stakeholder interview scheduling, and report review cycles. Simple properties with straightforward history and readily available documentation may complete within 1-2 weeks, while complex sites with extensive operations, limited historical records, or multiple stakeholders requiring coordination may extend 4-6 weeks. Phase 2 ESA duration depends on investigation scope with limited sampling (3-5 soil borings, 2-3 monitoring wells) potentially completing field work within 1 week followed by 2-3 weeks laboratory analysis and reporting, totaling 3-4 weeks. Comprehensive Phase 2 investigations with extensive drilling, multiple monitoring well installations, and phased sampling strategies may require 6-12 weeks or longer. Phase 3 remediation timeline spans from single-day excavation projects removing limited contaminated soil volume to multi-year in-situ treatment systems operating until cleanup objectives achieved, with typical projects ranging 3-18 months including planning, regulatory approval, implementation, and verification sampling.

3. What qualifications should Environmental Professionals conducting ESA in Indonesia possess?

Qualified Environmental Professionals conducting ESA should possess relevant educational background including environmental engineering, geology, environmental science, or related disciplines, minimum 3-5 years experience conducting environmental assessments and contamination investigations, professional credentials including certification as Environmental Management Expert (Ahli Lingkungan) by KLHK for AMDAL-related work in Indonesia, understanding of applicable regulatory frameworks including KLHK requirements and AMDAL procedures, and technical competence in site investigation methods, sampling protocols, and data interpretation. International projects may require professionals meeting ASTM E1527 standards including Bachelor's degree in science or engineering discipline, minimum 3 years relevant experience, and possession of Professional Engineer or Professional Geologist licenses in jurisdictions requiring such credentials. Consulting firms conducting ESA typically maintain multidisciplinary teams including geologists, environmental engineers, hydrogeologists, and risk assessment specialists providing comprehensive capabilities across assessment phases. ISO 17025 accredited laboratories conducting sample analysis require separate qualifications including method certification, quality management systems, and proficiency testing participation.

4. What costs should property stakeholders anticipate for each ESA phase in Indonesia?

Phase 1 ESA costs typically range IDR 25-65 million depending on site size, complexity, historical research requirements, and report preparation scope, with simple properties at lower range and complex industrial sites with extensive operations requiring comprehensive review at upper range. Phase 2 ESA costs vary dramatically based on investigation scope with limited reconnaissance sampling (3-5 soil borings, 2-3 monitoring wells) costing IDR 75-150 million, moderate investigations IDR 150-400 million, and comprehensive characterization exceeding IDR 500 million for large sites requiring extensive drilling, multiple monitoring wells, and comprehensive analytical suites. Laboratory analytical costs constitute substantial Phase 2 expense component, varying IDR 2-8 million per soil sample and IDR 3-12 million per groundwater sample depending on parameters analyzed. Phase 3 remediation costs span widest range from IDR 50-200 million for limited excavation projects removing several cubic meters contaminated soil to IDR 2-10 billion for complex remediation systems treating large volumes or implementing long-term groundwater treatment. Cost estimation requires site-specific assessment considering contamination extent, selected technologies, regulatory compliance requirements, and project schedule constraints.

5. How do Indonesian ESA standards compare with international practices and requirements?

Indonesian ESA practice largely follows international standards particularly ASTM E1527 for Phase 1 assessments and ASTM E1903 for Phase 2 investigations, adapted to local regulatory context and available resources. International consultants operating in Indonesia typically apply ASTM standards ensuring consistency with global client requirements and financing institution expectations, while incorporating Indonesian-specific elements including KLHK regulatory database review, AMDAL document examination, and SNI standards reference where established. Key differences include greater reliance on international quality standards (Dutch Quality Standards, WHO guidelines, USEPA criteria) given limited Indonesian soil quality standards development, environmental agency involvement varying by jurisdiction with coordination between KLHK, provincial, and municipal authorities sometimes creating complexity, and remediation approval processes following Indonesian regulatory procedures potentially differing from streamlined approaches in developed countries. Laboratory capabilities prove generally adequate for standard analyses though specialized testing may require international laboratory utilization. Overall, Indonesian ESA practice meets international quality standards when conducted by qualified consultants following recognized methodologies, providing comparable due diligence value for property stakeholders regardless of jurisdiction.

6. What happens if Phase 2 ESA identifies contamination exceeding regulatory standards?

Contamination discovery triggering regulatory thresholds requires notification to Ministry of Environment and Forestry or provincial environmental agency depending on jurisdiction, followed by Phase 3 remediation planning addressing cleanup approach, schedule, and performance objectives. Property stakeholders face several options including remediation implementation achieving unrestricted use standards allowing property development without constraints, risk-based management implementing institutional controls (deed restrictions, engineering controls) managing residual contamination where complete removal infeasible or cost-prohibitive, transaction renegotiation where buyer and seller negotiate purchase price adjustment, seller-funded remediation, or escrow arrangements addressing cleanup costs, or transaction termination where contamination severity creates unacceptable risk or remediation costs exceed property value. Liability allocation depends on contamination timing and responsible party identification, with historical contamination potentially attributable to previous owners or operators, though Indonesian environmental law increasingly emphasizes current owner responsibility regardless of contamination source. Professional environmental consultants assist stakeholders evaluating remediation options, estimating costs, developing regulatory approval strategies, and structuring transaction terms appropriately allocating environmental risks and cleanup responsibilities between parties.

7. How does AMDAL requirement interact with Environmental Site Assessment process?

AMDAL (Analisis Mengenai Dampak Lingkungan or Environmental Impact Assessment) constitutes separate but complementary process to Environmental Site Assessment, with AMDAL required for major development projects based on scale and sector criteria established by KLHK regulations, while ESA addresses property contamination assessment for transaction due diligence and liability protection. Integration occurs through baseline environmental quality characterization component of AMDAL documentation (KA-ANDAL, ANDAL sections) incorporating soil and groundwater quality data similar to Phase 2 ESA sampling, allowing ESA results supporting AMDAL preparation when timing permits coordination. Projects discovering contamination during AMDAL baseline studies may require remediation before development proceeds, with remediation plan incorporated into Environmental Management Plan (RKL) section and ongoing monitoring included in Environmental Monitoring Plan (RPL) section. Conversely, development projects proceeding without initial ESA may conduct investigations triggered by AMDAL baseline sampling identifying potential contamination, essentially performing ESA elements within AMDAL framework. Optimal approach involves early ESA completion before AMDAL preparation, identifying contamination requiring remediation and enabling baseline characterization after cleanup, though project schedules may necessitate parallel processes requiring careful coordination between ESA and AMDAL consultants.

8. What remediation approach proves most cost-effective for typical Indonesian contamination scenarios?

Cost-effectiveness depends on site-specific factors including contamination type, extent, site characteristics, and project objectives, though general guidance identifies excavation as most cost-effective for limited volume contamination (under 100 cubic meters) where disposal costs remain reasonable, bioremediation for petroleum hydrocarbon soil contamination across larger areas where extended timeframes acceptable, soil vapor extraction for volatile organic contamination in permeable unsaturated soils, and monitored natural attenuation for low-risk groundwater contamination where active remediation provides limited incremental benefit. Indonesian context favors excavation given relatively lower labor costs compared to developed countries, available disposal capacity at licensed landfills accepting contaminated materials, and regulatory preference for removal approaches providing definitive cleanup versus in-situ technologies requiring long-term monitoring and institutional controls. Technology selection should consider total lifecycle costs including initial capital investment, operational costs, monitoring requirements, regulatory compliance expenses, and opportunity costs from delayed property use, rather than solely focusing on initial implementation costs. Professional remediation consultants conduct feasibility analyses comparing alternatives across technical effectiveness, cost, schedule, regulatory acceptance, and stakeholder preference dimensions, recommending optimal approach balancing competing objectives and constraints specific to individual projects.

Essential ESA Terminology Glossary

Key terms for understanding Environmental Site Assessment processes in Indonesian regulatory context

AMDAL (Analisis Mengenai Dampak Lingkungan)

Environmental Impact Assessment required for major development projects in Indonesia, comprising documents including Terms of Reference (KA-ANDAL), Environmental Impact Analysis (ANDAL), Environmental Management Plan (RKL), and Environmental Monitoring Plan (RPL). AMDAL baseline studies may incorporate ESA elements characterizing existing contamination before project implementation.

ASTM E1527

American Society for Testing and Materials standard practice for Environmental Site Assessments establishing Phase 1 ESA methodology, scope, and reporting requirements. Widely adopted internationally including Indonesia for consistent due diligence practices meeting global lender and investor expectations despite being US-developed standard.

Bioremediation

Remediation technology employing microorganisms to degrade organic contaminants into harmless byproducts through natural metabolic processes. Applicable to petroleum hydrocarbons, some solvents, and biodegradable compounds, offering cost-effective in-situ treatment though requiring extended timeframes (6-36 months) compared to excavation approaches.

Conceptual Site Model (CSM)

Simplified representation of contamination sources, release mechanisms, affected media, transport pathways, and exposure receptors at site. CSM guides Phase 2 investigation design and remediation planning by documenting contamination understanding and identifying data gaps requiring additional investigation.

Dutch Quality Standards

Netherlands soil and groundwater quality standards frequently referenced for Indonesian industrial site assessments given comprehensive contaminant coverage and risk-based approach. Target values represent background concentrations while intervention values trigger mandatory remediation requirements. Commonly applied internationally where domestic standards lack coverage.

ISO 17025

International standard for testing and calibration laboratory competence requiring quality management systems, method validation, proficiency testing, and documented procedures. Environmental laboratories conducting ESA sample analysis should maintain ISO 17025 accreditation ensuring data quality and reliability supporting regulatory compliance and decision-making.

KLHK (Kementerian Lingkungan Hidup dan Kehutanan)

Ministry of Environment and Forestry administering Indonesia's environmental regulatory framework including contaminated site management, AMDAL requirements, environmental permits, and quality standards development. Primary regulatory authority for environmental compliance though provincial and municipal agencies implement certain provisions depending on jurisdiction.

Recognized Environmental Condition (REC)

Presence or likely presence of hazardous substances or petroleum products on property due to release, threat of release, or disposal under conditions indicating potential environmental contamination. RECs identified during Phase 1 ESA trigger recommendation for Phase 2 intrusive investigation confirming contamination presence and quantifying extent.

Remedial Action Plan (RAP)

Document describing remediation approach, implementation procedures, performance objectives, monitoring protocols, and schedule for contaminated site cleanup. RAP requires regulatory approval before remediation commencement, with agency review ensuring technical adequacy, regulatory compliance, and protection of human health and environment.

Soil Vapor Extraction (SVE)

In-situ remediation technology applying vacuum to unsaturated zone inducing controlled air flow removing volatile organic contaminants from soil. Effective for petroleum hydrocarbons and solvents in permeable sandy soils at shallow depths (under 10 meters), typically operating 6-24 months until cleanup objectives achieved.

SNI (Standar Nasional Indonesia)

Indonesian National Standards developed by National Standardization Agency (BSN) providing technical specifications including environmental quality parameters. SNI standards for soil and groundwater contamination remain under development with practitioners often referencing international standards (Dutch, USEPA) for assessment purposes until comprehensive Indonesian criteria established.

References and Data Sources:

1. ASTM International. (2013). Standard Practice for Environmental Site Assessments: Phase I Environmental Site Assessment Process (ASTM E1527-13).

Available through ASTM standards database at www.astm.org

2. ASTM International. (2019). Standard Practice for Environmental Site Assessments: Phase II Environmental Site Assessment Process (ASTM E1903-19).

Available through ASTM standards database at www.astm.org

3. SLP Environmental. (2023). Indonesia Phase 1 & 2 Environmental & Geotechnical Site Assessment.

https://www.slpenvironmental.com/project/indonesia-environmental-geotechnical/

4. Ministry of Environment and Forestry Indonesia (KLHK). (2019). Regulation P.38/2019 on Environmental Impact Assessment Categories.

https://jdih.maritim.go.id/cfind/source/files/permen-lhk/permenlhk-nomor-p.38-tahun-2019.pdf

5. Netherlands Commission for Environmental Assessment. (2023). Indonesia EIA Profile - Legislation at Project Level.

https://www.eia.nl/en/wp-content/uploads/2025/01/2023-12-14-Indonesia-Legislation-at-project-level.pdf

6. MyLegal Indonesia. (2024). Environmental Impact Assessment (AMDAL) Requirements and Procedures in Indonesia.

https://www.mylegalindonesia.com/environment/

7. AEI Consultants. (2022). Phase I Environmental Site Assessment Checklist.

https://aeiconsultants.com/phase-i-environmental-site-assessment-checklist/

8. Lender Consulting Services. (2024). The Basics of Phase II ESA Environmental Site Assessments.

https://www.lenderconsulting.com/phase-ii-environmental-site-assessments/

9. Pryco Global. (2025). Phase II ESA Sampling Methods Explained.

https://prycoglobal.com/blog/phase-ii-esa-sampling-methods/

10. US Environmental Protection Agency. (2025). Remediation Technology Descriptions for Cleaning Up Contaminated Sites.

https://www.epa.gov/remedytech/remediation-technology-descriptions-cleaning-contaminated-sites

11. GEO FORWARD. (2024). Remediation after Phase 2 Environmental Site Assessment.

https://www.geoforward.com/what-is-remediation-phase-2-environmental-site-assessment-phase-ii-esa/

12. Asian Development Bank. (2018). Environmental and Social Monitoring Report - Likupang Solar Project Indonesia.

https://www.adb.org/sites/default/files/project-documents/51209/51209-002-esmr-en.pdf

13. Association of Professional Geoscientists of Ontario. APGO Brownfields Guidance Document - Soil and Groundwater Assessment.

https://www.pgo.ca/files/APGO_Brownfields_Guidance_Document.pdf

14. DFM Development Services. (2024). What is Phase 3 Environmental Site Assessment for Remediation.

https://www.dfmdevelopment.com/news/environmental-compliance/phase-iii-environmental-site-assessment/

15. IPB University. (2023). Prof Hefni Effendi Presents Draft Environmental Study Standards to Environmental Office Staff.

https://www.ipb.ac.id/news/index/2023/09/prof-hefni-effendi-presents-draft-environmental-study-standards-to-environmental-office-staff-from-all-over-sulawesi/

Professional Environmental Site Assessment (ESA) Services

SUPRA International provides comprehensive Environmental Site Assessment services spanning Phase 1 preliminary investigations, Phase 2 intrusive sampling and laboratory analysis, and Phase 3 remediation planning and oversight for Indonesian commercial and industrial properties. Our multidisciplinary team combines environmental engineering, geology, hydrogeology, and regulatory expertise delivering assessments meeting international standards (ASTM E1527) while incorporating Indonesian regulatory requirements including KLHK frameworks and AMDAL integration. Services support property transaction due diligence, development planning, regulatory compliance, and contamination management requirements across diverse industrial sectors throughout Indonesian archipelago.

Need Environmental Site Assessment expertise and consultancy?

Contact us to discuss Phase 1, 2, or 3 ESA requirements and customized assessment solutions

Share:

If you face challenges in water, waste, or energy, whether it is system reliability, regulatory compliance, efficiency, or cost control, SUPRA is here to support you. When you connect with us, our experts will have a detailed discussion to understand your specific needs and determine which phase of the full-lifecycle delivery model fits your project best.